Web Inkjet

Frequently asked questions about our equipment for web inkjet applications.

-

Non-stop unwinding

-

Non-stop rewinding

-

Remoistening

-

Post-coating

-

Priming

Non-stop auto-splicing eliminates downtime caused by paper reel changes in web inkjet printing. This maximizes press output, improves efficiency, and lowers cost per print. At the same time, it reduces paper waste and frees operators to focus on higher-value tasks. The result: higher productivity and a smoother, more reliable workflow.

With a mono unwinder, every manual reel change can take around 15 minutes. If you need to change a reel every hour, this quickly adds up to a 25% loss in production capacity. The Contiweb CD-N Non-Stop Unwinder eliminates these costly interruptions. When the running reel is empty, it automatically splices the web to the new reel while production continues at full speed. The operator only needs to prepare the splice, a simple two-minute task that can be done at any convenient time during the splice cycle. For ergonomic loading, the CD-N is equipped with motorized lift arms that allow reels to be loaded safely from ground level.

Calculate your productivity gains with the Contiweb ROI Calculator

The Contiweb CD-N is an auto-splicer with two reel positions, allowing the next reel to be loaded and prepared while the first is running. As the expiring reel nears its end, a festoon (or accumulator) expands to build a paper buffer. The running reel is then stopped, and while the press is fed from the buffer, the splice is performed. The new reel accelerates to match press speed, ensuring production continues without interruption.

The Contiweb CD-N Non-Stop Unwinder is designed to eliminate downtime caused by reel changes. The CD-N has two reel positions, so while one reel is running, the next can be loaded and prepared in advance. Reel loading and splice preparation are safe, easy, ergonomic and take only two minutes. As the running reel nears its end, a festoon expands to create a paper buffer. The reel brought to a controlled stop, the expiring web is then cut, and the splice to the prepared reel is performed while both reels remain stationary. During this splice, the press is continuously fed from the buffer. Once complete, the new reel accelerates to press speed, ensuring seamless, uninterrupted production.

Watch how automatic splicing works and see how reel loading and splice preparation are done

A manual reel change on a mono unwinder takes around 15 minutes of lost production, even for trained and experienced operators. The press must slow down, stop, and later ramp back up, while the operator handles routine steps. If a reel is changed every hour, this downtime can reduce press capacity by 25% or more.

A manual reel change involves around 12 steps, including slowing down the press, cutting the web, unloading the empty core, loading and centering a new reel, taping, carefully threading the splice through the line at crawl speed to ensure it passes safely, and ramping the press back up to speed. Although the tasks are straightforward, they are disruptive and take the operator away from more valuable activities. Even with skilled operators, the process consumes around 15 minutes and leads to paper waste during restart. In busy production environments, these repeated interruptions add up to hours of lost output, higher substrate costs, and reduced overall efficiency.

Yes. The Contiweb CD-N Non-Stop Unwinder performs every reel change automatically while the press keeps running. It splices seamlessly to different paper types—whether grammage, coating, or reel width—without interruption.

Each manual reel change takes around 15 minutes, during which labor, energy, and paper are wasted. The CD-N eliminates this by executing the splice automatically while production continues. It can handle changes in grammage, coating, and reel width without issue, so operators save valuable time at every changeover. In addition, leftover reels can be processed down to the core, improving paper utilization and preventing unnecessary stock build-up. Together, these benefits ensure that auto-splicing remains highly valuable, even in short-run environments with frequent paper changes.

Contact Contiweb for more details

No. The Contiweb CD-N Non-Stop Unwinder is specifically designed for continuous-feed inkjet presses and ensures splices run safely through at full production speed. The system communicates with the press so the printheads retract at the right moment, avoiding any risk of contact.

The Contiweb CD-N combines exceptionally high splice quality with direct communication to the press. Every splice—whether overlap with a short tail or butt splice with no overlap—is produced with outstanding consistency and reliability. Before the splice reaches the print zone, the CD-N signals the press to retract the printheads briefly, preventing any risk of damage. Because the splice runs at full production speed, the loss of press time is negligible. By uniting this superior splice quality with synchronized press control, the CD-N ensures safe, reliable splicing and uninterrupted output, even at the highest web speeds.

Contact Contiweb to learn more about splice reliability in your press

The payback time for an auto-splicer depends on several factors, such as the price of the equipment, the amount of production lost during reel changes, the cost of wasted paper, and the operating costs that continue during downtime. When measured carefully, the impact of these losses is often higher than expected. Many customers recover the investment in a Contiweb CD-N in less than two years.

The return on investment for an auto-splicer depends on how often reels are changed and the costs that continue to accrue during downtime. Each manual reel change takes about 15 minutes, during which labor, energy, and press expenses accumulate, and additional paper waste occurs. When measured carefully, the total cost of lost production is often higher than expected. With a Contiweb CD-N, splicing is fully automatic, so operators spend less time on routine reel handling and more on valuable tasks. Because production continues without interruption, shift capacity increases. In peak periods, this higher output can reduce the need for overtime—or even remove the need for additional shifts.

Calculate your productivity gains with the Contiweb ROI Calculator

There are situations in which printing companies opt to rewind certain printed jobs instead of finishing them inline. Several factors contribute to this decision. One such factor is when the finishing process is outsourced to an external company. In these cases, rewinding the printed reel proves to be a practical choice. By sending the reel to an external finishing provider, better coordination and control can be achieved over the finishing process. This approach ensures that the external company receives a neatly wound reel, facilitating their handling and enabling them to perform specific finishing tasks with ease.

Another reason for choosing to rewind printed jobs is workflow optimization. At times, the finishing line may be occupied with other ongoing jobs or require specific setup configurations. By rewinding the printed reels, they can be temporarily stored and queued for finishing at a more opportune time. This flexibility in the workflow significantly enhances overall productivity, reduces bottlenecks, and ensures a seamless production process.

When utilizing a Contiweb CR-N non-stop rewinder in combination with a Contiweb CD-N non-stop unwinder, printers gain several additional benefits, including the capability of executing a coordinated splice. This refers to the process of making a splice at the exact same location when the paper reel is wound by the CR-N non-stop rewinder as the splice made at the beginning of the process by the CD-N non-stop unwinder. These splices align perfectly on top of each other. This synchronization is made possible due to the zero speed technology and paper buffer of the CR-N non-stop rewinder, which provides enhanced control over the splicing moment. The advantages of a coordinated splice include reduced waste and the assurance of having a printed roll of paper that matches the unprinted roll precisely.

The CR-N non-stop rewinder offers the option to be equipped with either shear or crush slitters for cutting purposes.

Shear slitting involves the use of sharp circular knives that move against the paper and cut through it. Shear slitting is known for producing clean and precise cuts, making it suitable for paper up to 350 g/m².

Crush slitting employs a sharp cut knives that press against a hardened roller. The cuts may be slightly less precise compared to shear slitting. However, crush slitting offers certain advantages. It allows for more frequent cuts, with a minimum distance between cuts. Additionally, during production, the position of the cuts can be manually adjusted, and the cut can be combined with perforation if desired.

The operator must insert a core into the CR-N non-stop rewinder to which a small piece of paper is attached, sufficient to reach the splice head. There, the adhesive tape should be stuck so that the CR-N non-stop rewinder can connect the empty reel to the printed paper coming out of the printing press.

The Contiweb CR-N non-stop auto splicer has lift arms that can move up and down. This operation is ergonomic, and requires no lifting crane. Also no reel shafts are required (when slitting is not selected).

The Contiweb CR-N non-stop auto splicer allows you to splice over to papers of different web widths, coatings and weights. This is very useful for short, fast-changing jobs.

The Contiweb CR-N non-stop auto splicer makes an overlap splice when joining two reels of paper.

The Contiweb CR-N non-stop auto splicer can handle paper reels with a diameter of up to 1,520 mm (60 inches) and a maximum weight of 1,600 kg.

Spare parts for Contiweb non-stop auto splicers are conveniently available in the Contiweb Parts Webshop. Sign up for an account and gain free access to Contiweb machine manuals and parts books, saving you valuable time by filtering your search for specific machine parts.

Plus, explore our Uptime Kits, specially curated with essential components to minimize downtime in the event of breakdowns, ensuring you have the necessary parts readily available in your own facility. Streamline your maintenance and keep your operations running smoothly with Contiweb.

Due to the use of water-based inks in roll-fed inkjet presses and the high printing speeds they can achieve, there is a need to dry prints quickly and at high temperatures. However, this fast and hot drying process can give rise to several problems.

The printed material may become wavy, making it difficult for signatures to lie flat. Another problem that can occur is the curling of paper edges. Both problems can create challenges in the finishing line. They may lead to congestion and downtime. Also, the overall appearance and quality of the final product may be impacted. In the worst case scenario, the customer may reject the products.

To gain more insight into these problems, you can refer to this blog post, which provides further details on these issues and their potential impact on printed materials.

With inline finishing configurations increasing in popularity in web inkjet, the DFA's option to add silicone is gaining importance. Many finishing systems use a lot of moving parts like rollers and wheels which, in time, can leave unwanted scratches and scuffs. These can cause image damage, reducing the value of the printed product.

Contiweb has extensive knowledge of moisture and silicone application in web printing. The experience we've gained in the heat set web offset industry has been successfully applied to inkjet. Contiweb has an installed base of more than 600 remoistening and silicone applicators at top quality printers around the world.

The purpose of silicone application is to minimize marking or scuffing during post-processing equipment handling. The protective effect of the silicone oil is temporary. Within a day, the silicone oil is completely absorbed by the paper. Once absorbed, the silicone oil no longer serves its protective function and has no impact on the appearance of the final product. The application of silicone oil by the Contiweb Digital Fluid Applicator does not affect the remoistening.

The Contiweb Digital Fluid Applicator utilizes fabric sleeves for several advantageous reasons. Fabric sleeves are carefully crafted with a distinctive engraved pattern on their surface. These engravings consist of precisely sized and spaced cells, forming a meticulously controlled system for storing and releasing moisture. The result is an exceptional distribution of fluids across the paper web, ensuring uniform coverage.

Moreover, textile sleeves possess inherent resilience and compression properties. When pressure is applied due to unevenness of the printed paper, the sleeve undergoes a slight deformation. This adaptability helps maintain a consistent contact surface between the sleeve and the paper, enabling reliable fluid transfer. By accommodating variations in the paper surface, textile sleeves contribute to consistent and accurate application of fluid, ultimately improving overall printing performance.

The durability of fabric sleeves in the Contiweb Fluid Applicator can vary depending on the specific printing application. While fabric sleeves offer excellent and uniform fluid coverage on paper, they are not immune to wear. The lifespan of fabric sleeves is highly dependent on the operating conditions and printing practices employed.

Different printers experience varying durations of sleeve usage. Some printers may utilize the same fabric sleeve for several months without requiring replacement, while others may find it necessary to replace sleeves after only a few weeks of use. The longevity of fabric sleeves is influenced by factors such as print volume, print speed, substrate characteristics and ink fluid formulations.

Replacing the fabric sleeves is a straightforward procedure. The roller containing the worn sleeve is detached from the Digital Fluid Applicator, the worn sleeve is cut open and removed from the roller. The new fabric sleeve is then shrunk tightly around the roller with hot water and the roller is reinstalled into the machine. As the roller rotates through the pan and becomes moistened, it is ready to resume its function. Printers who do not want to lose any production time, prepare an extra set of rolls with new sleeves.

Contiweb provides convenient access to replacement sleeves through the Contiweb Parts Webshop.

Surfactant and silicone oil are not provided as standard with the purchase of a Digital Fluid Applicator. They can be sourced from various suppliers of printing consumables.

Spare parts for Contiweb Digital Fluid Applicators are conveniently available in the Contiweb Parts Webshop. Sign up for an account and gain free access to Contiweb machine manuals and parts books, saving you valuable time by filtering your search for specific machine parts.

Plus, explore our Uptime Kits, specially curated with essential components to minimize downtime in the event of breakdowns, ensuring you have the necessary parts readily available in your own facility. Streamline your maintenance and keep your operations running smoothly with Contiweb.

Post-coating can boost quality by adding a gloss or matt coating to the printed items, enhancing the look and feel. It also protects items like postcard mailers that could otherwise be damaged during mail handling. For self-mailers, the addresses are printed on the items themselves, so post-coating prevents them for becoming unreadable.

The Contiweb Variable Coater is a closed-loop controlled system designed to revolutionize coating application. Powered by our patented automated metering technology, this advanced system ensures the precise and optimal amount of coating is applied to the web, eliminating the risks of overcoating or undercoating.

Flexibility is at the core of the Contiweb Variable Coater. Adjusting to changing web widths or coating layers is now a seamless process. Thanks to its innovative design, you can seamlessly transition between different web widths and coating requirements without any machine standstill. This means you can effortlessly queue small print jobs with varying coating layers and web widths, eliminating costly interruptions for replacing machine parts.

Automation lies at the core of Contiweb's product strategy and development programs. Drawing on its expertise in heat-set web offset printing, Contiweb recognizes the significance of interconnected equipment that shares process information to achieve high-level automation. In today's world of web inkjet printing, a similar approach is essential.

With regards to the Variable Coater, depending on press requirements and communication capabilities, Contiweb will design an interface that facilitates seamless communication between the press and central control from the press console. This tailored interface ensures smooth integration and optimal performance based on the specific requirements and capabilities of the printing press.

In situations where the Variable Coater is not installed inline with a press, Contiweb takes steps to establish an interface with both the unwinder and rewinder units.

Today only aqueous based coatings can be used in the Contiweb Variable Coater. Aqueous based coatings are generally more affordable compared to UV coatings, making them a cost-effective option for many print projects. Also, they are more environmentally friendly due to their lower VOC content, water-based formulation, reduced energy requirements, easier waste disposal, and better regulatory compliance.

There is a wide range of manufacturers offering aqueous-based coatings and you are free to select the supplier that aligns best with your preferences and requirements.

While UV coatings are still the preferred choice for applications requiring extremely high gloss and reflectivity, advancements in aqueous coating technology have significantly improved their gloss capabilities. Coating manufacturers have developed specialized aqueous coatings that can achieve gloss levels closer to those achieved by UV coatings. These advancements provide more options for achieving desirable gloss rates with aqueous-based coatings.

Spare parts for the Contiweb Variable Coater are conveniently available in the Contiweb Parts Webshop. Sign up for an account and gain free access to Contiweb machine manuals and parts books, saving you valuable time by filtering your search for specific machine parts.

Plus, explore our Uptime Kits, specially curated with essential components to minimize downtime in the event of breakdowns, ensuring you have the necessary parts readily available in your own facility. Streamline your maintenance and keep your operations running smoothly with Contiweb.

Contiweb's Variable Coater lets printers use standard offset paper that they can treat themselves, achieving high-quality print results and giving them access to an unlimited range of paper grades. It also saves them costs by eliminating the need to purchase expensive paper mill treated paper. Additionally, they won't be at the mercy of fluctuating paper availability, providing them with greater control and reliability.

The Contiweb Variable Coater uses the patented automated metering technology to very precisely apply the coating layer on the web, causing no standstill during a web width change or when changing the coating layer thickness. You can queue small print jobs with ever-changing coating layer and web width, without costly interruptions for replacing machine parts.

Case studies show a payback period of less than two years. Depending on the customer, savings can include:

- Paper (affordable offset paper instead of expensive mill treated inkjet paper)

- Ink (reduced consumption)

- Handling (no cleaning costs of anilox and doctor blade, no additional personnel to exchange sleeves and anilox)

- Consumables (no replacements needed for sleeves or anilox)

Please contact us for a payback period calculation for your specific situation.

Paper mills do offer treated paper for web inkjet printing, but there are relatively few variants available and their availability fluctuates. The paper mills normally add a coating that gives the best average result with different kinds of inks, meaning that the coating is not optimized for each job.

The Contiweb Variable Coater lets you prime low-cost offset paper in-house. This improves adhesion while significantly improving printability. It can be optimized for the specific ink that you are using, improving print quality and reducing ink consumption. Dot gain and ink absorbency are lower. That means using less ink, or the same amount of ink but higher density and so more attractive printing.

When the Contiweb Variable Coater is integrated inline with a web inkjet press, Contiweb will design an interface that enables seamless communication between the press and central control from the press console. In the case of standalone installation, Contiweb will establish an interface with both the unwinder and rewinder units.

Spare parts for the Contiweb Variable Coater are conveniently available in the Contiweb Parts Webshop. Sign up for an account and gain free access to Contiweb machine manuals and parts books, saving you valuable time by filtering your search for specific machine parts.

Plus, explore our Uptime Kits, specially curated with essential components to minimize downtime in the event of breakdowns, ensuring you have the necessary parts readily available in your own facility. Streamline your maintenance and keep your operations running smoothly with Contiweb.

Web Offset

Frequently asked questions about our equipment for heat set web offset applications.

-

Drying and chilling

-

Non-stop flying pasting

The Contiweb hot air dryers offer an innovative solution for recycling energy from ink solvents to fuel combustion and maintain dryer temperatures. As the air containing evaporated solvents reaches the end of the dryer section, it is directed into integrated combustion chambers for incineration. The exhaust air is then thoroughly cleaned and recirculated back into the dryer section, effectively reusing the existing heat.

One notable advantage of the Contiweb drying process, which incorporates the integrated afterburner, is its significant reduction in energy consumption compared to traditional systems. Depending on factors such as ink coverage and speed, the integrated afterburner can contribute to significant energy savings. This efficiency improvement benefits both cost savings and environmental sustainability.

If you are interested in exploring the possibilities for reducing gas consumption and achieving cost savings with your existing dryer, Contiweb's Gas Reduction Enhancement program offers a viable solution.

Contiweb dryers offer the advantage of being equipped with frequency drives that allow continuous adjustment of fan speeds, ranging from 0 to 100%. In contrast, fans in conventional dryers typically operate at fixed speeds of either 50% or 100% of their nominal speed, often resulting in unnecessary energy consumption. By utilizing the fully variable speed capabilities of frequency drives, the power consumption of Contiweb dryers can be significantly reduced by up to 50%. This not only leads to cost savings but also provides the added benefit of extending the lifespan of motors, motor bearings, V-belts, and fans.

Recognizing that not all printing companies are ready to invest in a new energy-efficient dryer, Contiweb offers an appealing solution known as the Electrical Power Reduction enhancement. This enhancement allows printing companies to achieve substantial electricity consumption savings with their existing dryers.

Contiweb hot air dryers offer a range of benefits, including significant reductions in gas and electricity consumption, as well as lower CO2 emissions.

Through the post-combustion of solvents, Contiweb dryers can achieve remarkable gas consumption reductions of up to 70% compared to conventional dryers. This represents a substantial decrease in resource usage and associated costs. Furthermore, the implementation of variable frequency drives to power the dryer fans allows for electricity consumption reductions of up to 50%. This not only contributes to cost savings but also has a positive impact on CO2 emissions, promoting environmental sustainability. You can get an indication of your potential savings with the Sustainable Savings Estimator.

It's important to note that the extent of cost savings and CO2 reduction achieved will vary depending on factors such as ink coverage and speed. To obtain a precise calculation tailored to your specific requirements, please reach out to the Contiweb sales department. They possess the expertise and knowledge to assist you in determining the potential benefits and conducting a comprehensive cost analysis.

Many governments around the world offer subsidies and incentives to businesses that invest in capital goods aimed at reducing their carbon footprint and promoting sustainability. These subsidies are part of broader environmental and climate change initiatives to encourage businesses to adopt cleaner technologies and practices. The availability and nature of these subsidies can vary depending on the country and region.

Government agencies, environmental departments, or industry associations can provide information on available programs and eligibility criteria. Consulting with sustainability experts or financial advisors can also help navigate the subsidy landscape and identify the most relevant opportunities for reducing the carbon footprint through capital goods investments.

Contiweb offers a comprehensive range of service programs for its dryers to ensure optimal customer support and long-term equipment performance. When you choose Contiweb equipment, you enter into a lasting partnership built on mutual commitment, enabling continuity in the Heat Set Web Offset market. Our Service Support Agreements are designed based on these fundamental principles.

We provide four distinct packages that cater to various needs and maintenance philosophies. The key objectives of our service programs are as follows:

- Ensure top level customer service

- Increase uptime

- Safeguard low operating costs

- Ensure compliance and sustainability

- Keep maintenance costs predictable and competitive

Spare parts for Contiweb dryers are conveniently available in the Contiweb Parts Webshop. Sign up for an account and gain free access to Contiweb machine manuals and parts books, saving you valuable time by filtering your search for specific machine parts.

Plus, explore our Uptime Kits, specially curated with essential components to minimize downtime in the event of breakdowns, ensuring you have the necessary parts readily available in your own facility. Streamline your maintenance and keep your operations running smoothly with Contiweb.

In today's uncertain economic climate, investing in new capital equipment can pose challenges for many companies. Considering used machines can be an intriguing alternative.

Contiweb recognizes this need and maintains a dynamic inventory of used dryers. These machines undergo meticulous inspection, repairs, and, if desired, upgrades to ensure their quality and reliability. When a used piece of equipment leaves Contiweb's facilities, it is designated as Certified Pre-Owned, providing customers with added confidence. Furthermore, Contiweb offers a 6-month warranty with each Certified Pre-Owned machine.

The splice preparation for automatic splicing is a quick and straightforward task that only takes 2 minutes to complete. It can be easily performed while the production is ongoing. The operator's involvement is minimal and involves applying a linear adhesive tape for the straight-tape splice on the paper. The time required for splice preparation is limited to the actual preparation process itself.

If there are multiple buffer positions for paper reels available, the operator has the option to prepare and set up several paper reels for automatic changeover. This allows the operator to work on other tasks while the prepared reels are ready for seamless transitions.

Contiweb's non-stop flying pasters allow you to easily splice over to papers of varying coatings and weights. This feature is particularly beneficial for short and fast-changing printing jobs. Additionally, you can effortlessly utilize rest reels.

The Contiweb non-stop flying pasters are equipped with a standard overlap splice mechanism. In an overlap splice, the expiring roll and the new roll overlap, with the leading edge of the new roll positioned on top of the trailing edge of the expiring roll. This overlap is secured using adhesive tape. Overlap splices are known for their simplicity and reliability, allowing for seamless roll changes during the printing process. Contiweb non-stop flying pasters have a successful splicing rate of over 99.7%.

As an optional feature a tail cutter can be installed, to remove the loose end of the previous web that occurs after a paste cycle. By removing the tail, potential disturbances in the folding process are eliminated.

The Contiweb FD non-stop flying paster is equipped to handle reels with a diameter of up to 1,524 mm (60 inches) with a maximum weight of 7,500 kg, which provides a multitude of advantages and benefits for printing operations. It enables a significant increase in paper capacity, reduces the number of required pastes, lowers costs, minimizes web break risks, and provides operational flexibility for web operations, particularly those with multiple presses. This advanced capability sets a new benchmark in reel processing, revolutionizing the efficiency and performance of printing operations.

The Contiweb FB is available in two versions to cater to specific needs. A version designed for newspaper applications with a reel weight capacity of 1,000 kg and a version tailored for (semi-) commercial applications with a higher reel weight capacity of 1,600 kg. The FB can handle reels with a maximum diameter of 1,270 mm (50 inches).

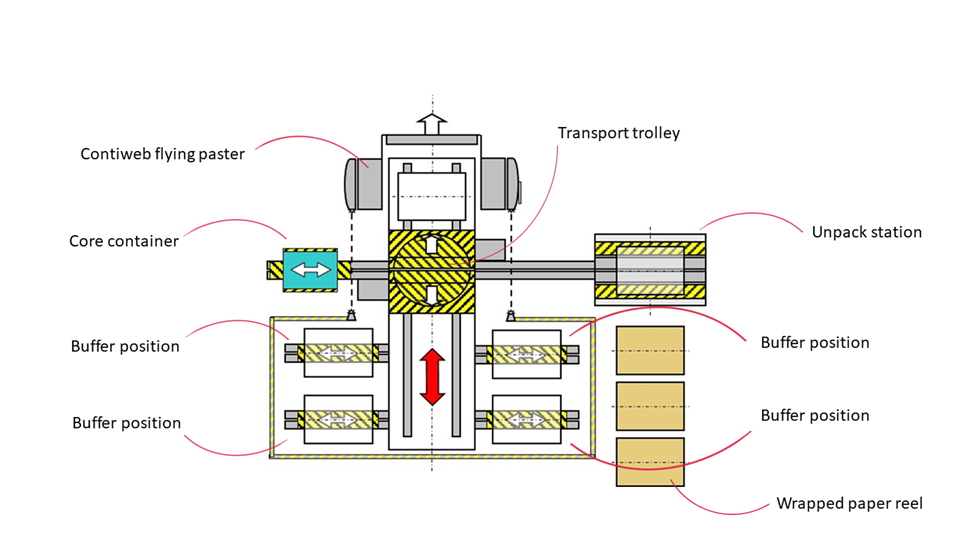

Contiweb offers comprehensive reel logistics systems that can be customized to complement its state-of-the-art non-stop flying pasters. Stand-alone storage solutions and reel buffering systems are defined by advanced capabilities and ultimate reliability. The objective is to minimize the required operator attendance whilst ensuring operational reliability, thus reducing costs. In a system with four buffer positions, up to seven reels (one at each buffer position, one in the waiting position and two in the paster) can be prepared at the same time, and no further operator involvement is required until all seven reels are being used, as the empty reels are automatically collected in the core container. You can see an example of this set up below.

Contiweb extensive experience in designing systems for commercial web applications and for newspaper applications requiring an interface with multiple pasters. The additional Contiweb advantages are full automation and complete hardware and software integration with Contiweb non-stop flying pasters and press systems. No third party involvement is required for the installation and electronic integration of the reel logistics system with the reel stands.

Contiweb offers a comprehensive range of service programs for its non-stop flying pasters to ensure optimal customer support and long-term equipment performance. When you choose Contiweb equipment, you enter into a lasting partnership built on mutual commitment, enabling continuity in the Heat Set Web Offset market. Our Service Support Agreements are designed based on these fundamental principles.

We provide four distinct packages that cater to various needs and maintenance philosophies. The key objectives of our service programs are as follows:

- Ensure top level customer service

- Increase uptime

- Safeguard low operating costs

- Ensure compliance and sustainability

- Keep maintenance costs predictable and competitive

Spare parts for Contiweb non-stop flying pasters are conveniently available in the Contiweb Parts Webshop. Sign up for an account and gain free access to Contiweb machine manuals and parts books, saving you valuable time by filtering your search for specific machine parts.

Plus, explore our Uptime Kits, specially curated with essential components to minimize downtime in the event of breakdowns, ensuring you have the necessary parts readily available in your own facility. Streamline your maintenance and keep your operations running smoothly with Contiweb.

In today's uncertain economic climate, investing in new capital equipment can pose challenges for many companies. Considering used machines can be an intriguing alternative.

Contiweb recognizes this need and maintains a dynamic inventory of used non-stop flying pasters. These machines undergo meticulous inspection, repairs, and, if desired, upgrades to ensure their quality and reliability. When a used piece of equipment leaves Contiweb's facilities, it is designated as Certified Pre-Owned, providing customers with added confidence. Furthermore, Contiweb offers a 6-month warranty with each Certified Pre-Owned machine.