-

Fully automatic non-stop reel splicing for sheet-fed printing

-

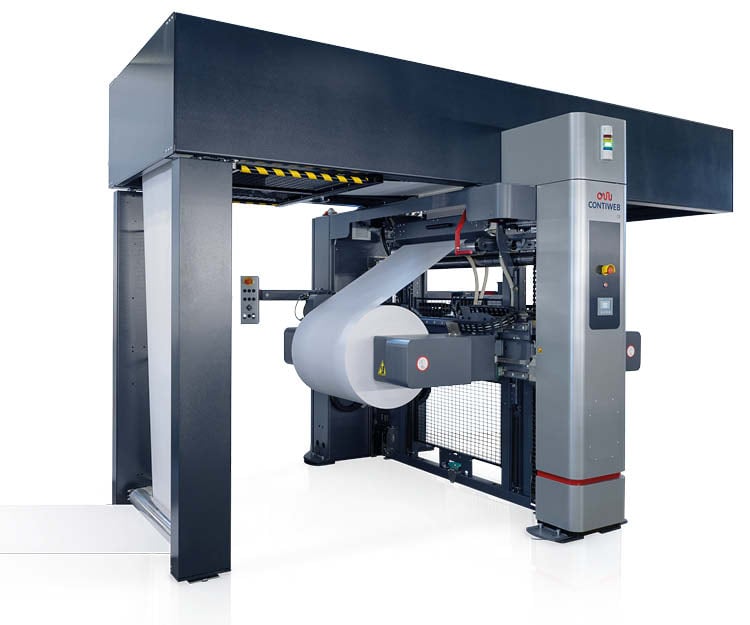

Contiweb CB-N Non-Stop Unwinder

-

The perfect complement to your reel sheeter

Maximizing productivity for sheetfed offset presses

Today’s state-of-the-art sheetfed offset presses run at extremely high speeds. To fully leverage this capability, many forward-thinking printers are adopting reel-fed printing with reel sheeters and an unwinder to feed the substrate. This setup not only lowers paper costs by using more economical reel stock, but also boosts press performance and improves handling of thin or lightweight substrates. At the same time, market demand is shifting toward shorter runs across a wider range of substrates—leading to more frequent reel changes.

With a basic mono unwinder attached to the reel sheeter, every reel change interrupts production and inevitably reduces productivity. Even with a skilled operator team, slowing the press down and ramping it back up to full speed typically takes 12 to 15 minutes. During this time, little or no sellable print is produced—wasting valuable capacity on presses designed to deliver very high volumes.

The Contiweb CB-N Non-Stop Unwinder eliminates this bottleneck. By automatically splicing the expiring reel to a fresh one with a single butt splice, production continues without interruption—enabling printers to maximize press performance. Another key advantage is reduced paper waste: every stop generates waste, but with non-stop auto-splicing, these losses are kept to a minimum.

With productivity gains of 15–30% and lower waste, the investment in a Contiweb CB-N Non-Stop Unwinder typically pays for itself within two years.

Benefits

- Maximized press output: Non-stop unwinding eliminates manual reel changes and downtime, increasing production by 15–30%.

- Greater operator flexibility: Splice preparation takes only two minutes and can be done at any time during production, freeing operators to focus on other tasks.

- Reduced paper waste: Avoiding press stops saves about 60 make-ready sheets each time.

- Exceptional splice reliability: Consistent performance with 99.8% or higher reliability.

- Versatile splicing options: Seamlessly splice reels of different web widths, coatings, and weights. The CB-N handles rest reels without diameter restrictions.

- Splice on demand: Splicing can be triggered at any time without stopping production.

- Ergonomic reel loading: Motorized lift arms load reels directly from ground level—safe, ergonomic, and crane-free.

- Fast ROI: In most cases, the investment pays back in less than two years.

Features

- Single butt splice as standard.

- Spot splicing centers the splice on a sheet, ensuring the sheet runs smoothly through the press.

- Motorized arms for lifting reels from ground level.

- No reel shafts required.

- Supports paper weights from 30 g/m² to 350 g/m² (18 pt / 0.457 mm) and films as thin as 50 µm.

- Maximum winding speed: 300 m/min (984 ft/min).

- Available in 42" (1100 mm) web width.

How the Contiweb CB-N Non-Stop Unwinder works

The Contiweb CB-N is an automatic splicer designed for seamless integration with reel sheeters in sheetfed offset printing. It enables fully automated reel changes without stopping the press, ensuring uninterrupted production.

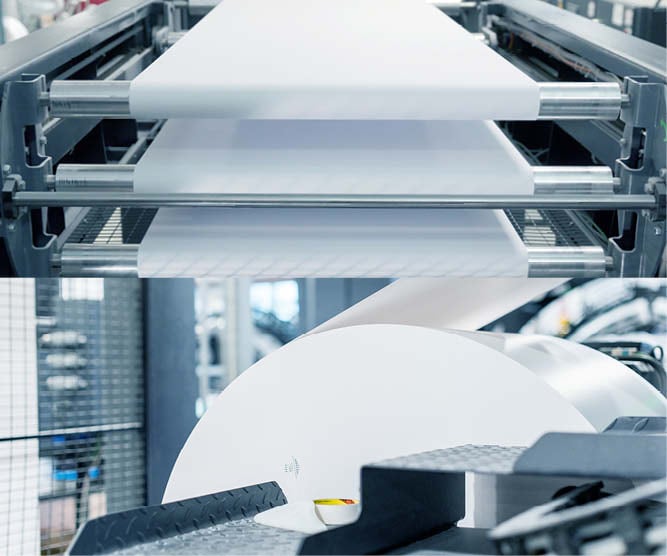

During the splice cycle, as the running reel nears its end, the festoon is filled with substrate to create a buffer. The expiring reel is then brought to a controlled stop while the new reel is held in place. The reel sheeter continues drawing from the festoon, allowing the splice to be made without interrupting production. This “zero-speed splicing” method minimizes stress on the web and ensures splice reliability of more than 99.8%, regardless of tape alignment, paper quality, or operator skill.

The CB-N can splice at any reel diameter—including small rest reels—providing maximum flexibility for changing substrate types or web widths. Reel changes can be triggered automatically by remaining diameter or a predefined paper length.

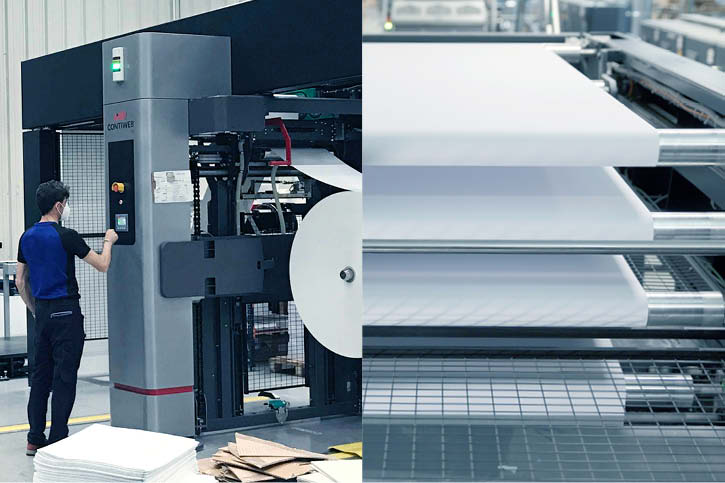

Reel loading is safe, ergonomic, and crane-free. Motorized lift arms allow reels to be loaded directly from ground level. Splice preparation takes just two minutes and can be completed while production continues, decoupling reel changes from job changes.

Seaway Printing:

100,000+ sheets per shift with one operator

Seaway Printing, a U.S.-based specialist in bound publications, has achieved new levels of performance on its Heidelberg Speedmaster XL106 offset press by integrating the Contiweb CB-N Non-Stop Unwinder with a CutStar reel sheeter.

The result: consistent shift outputs of more than 100,000 sheets with just one operator, and an Overall Equipment Effectiveness (OEE) of 65–70%. Heidelberg considers it one of the most productive sheetfed presses in the world. With fewer manual tasks and uninterrupted production, Seaway has transformed high-volume sheetfed printing into a lean, single-operator workflow.

Trusted by

Would you like to know more?

If you are interested in Contiweb's non-stop unwindings solutions and you would like to know more, then please don't hesitate to contact us!

Your Contact

Rob Bosman

Sales Director

+31 6 51 20 27 55

sales@contiweb.com