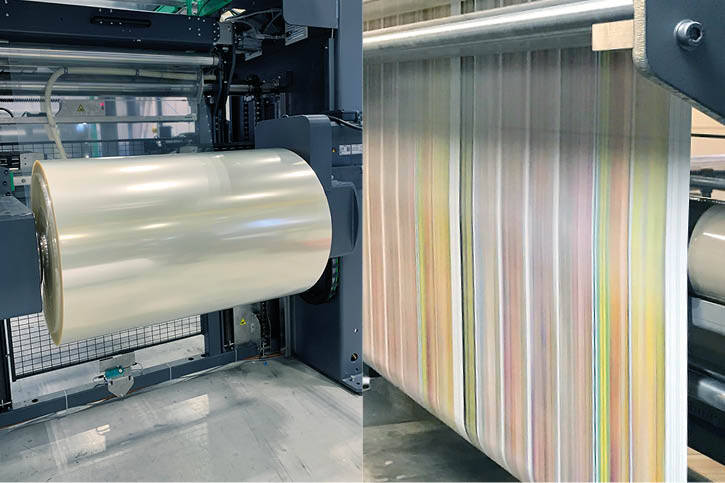

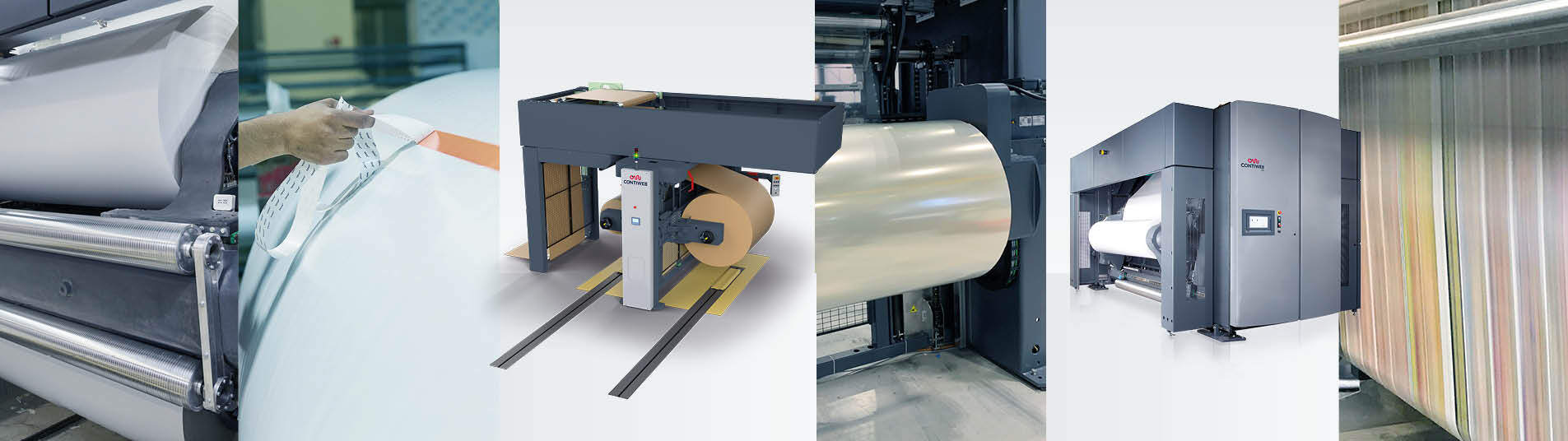

Comprehensive auto-splicing solutions for diverse applications

Contiweb’s auto-splicing systems boost productivity with seamless reel changes, eliminating production stops. This reduces downtime and ensures continuous operation—ideal for fast-paced printing, packaging production and converting lines.

Our technology serves multiple industries, including packaging, converting, and printing. Designed for high-speed applications, our solutions improve material flow, maximize uptime, and cut waste—essential for OEE-driven production.

Contiweb has extensive experience integrating our machines into production lines from other manufacturers. Our solutions seamlessly interface with existing setups, helping customers optimize their production environments for maximum performance.