-

CD-N Non-Stop Unwinding Equipment

-

Keeps digital print jobs moving continuously

-

Automatically change paper reels without production stop

Keep digital print jobs moving continuously

Benefits

- Save production and labor hours: Non-stop winding eliminates manual reel changes that cause downtime, significantly increasing press uptime.

- Increased operator flexibility: Splice preparation can be done at any convenient time during production—allowing operators to focus on other tasks.

- Fast and simple splice preparation: Preparing a splice takes just two minutes.

- Exceptional splice reliability: Achieve consistent splice performance of 99.8% or higher.

- Versatile splicing options: Splice to reels with different web widths, coatings, and weights—ideal for short runs and fast job changes.

- On-demand splicing: Splices can be made on the fly without stopping production. The CD-N non-stop unwinder easily handles rest reels, with no restrictions on reel diameter.

- Smart integration with your press: If your press supports it, Contiweb equipment can signal the press ahead of a splice—allowing print heads to lift in time. It can even detect splices made by the paper mill.

- Ergonomic reel loading: Motorized lift arms move up and down so reels can be loaded from ground level—no crane needed.

- Additional advantages include fewer errors during splice preparation, less risk of web loss due to time pressure, reduced paper waste, smoother startups, and energy savings through faster changeovers.

Features

- Horizontal festoon for zero-speed splicing.

- Lap splice as standard; butt splice available as an option.

- Motorized arms for lifting reels on and off the loading platform.

- No reel shafts required.

- Compatible with all web inkjet presses.

- Supports paper weights up to 350 g/m² (18 pt).

- Maximum winding speed: 330 m/min (1080 ft/min).

- CD-N non-stop unwinder available in 22" (560 mm), 30" (770 mm), 42" (1100 mm), and 61" (1550 mm) versions.

CD-N non-stop unwinder

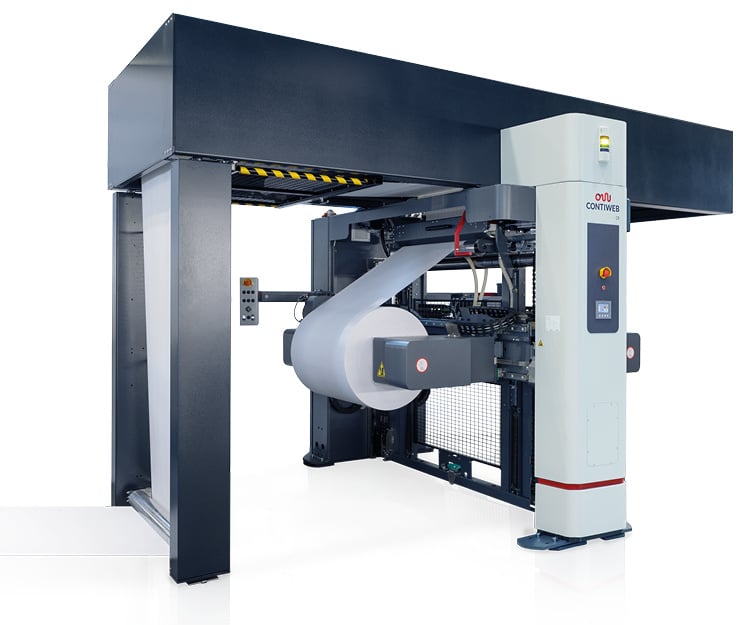

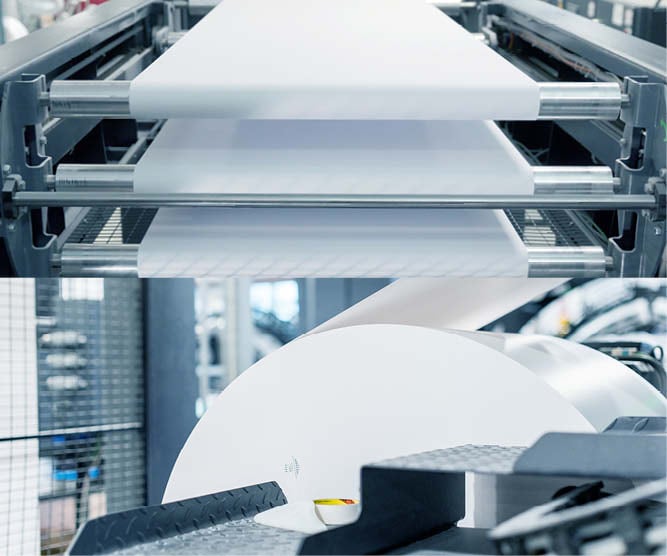

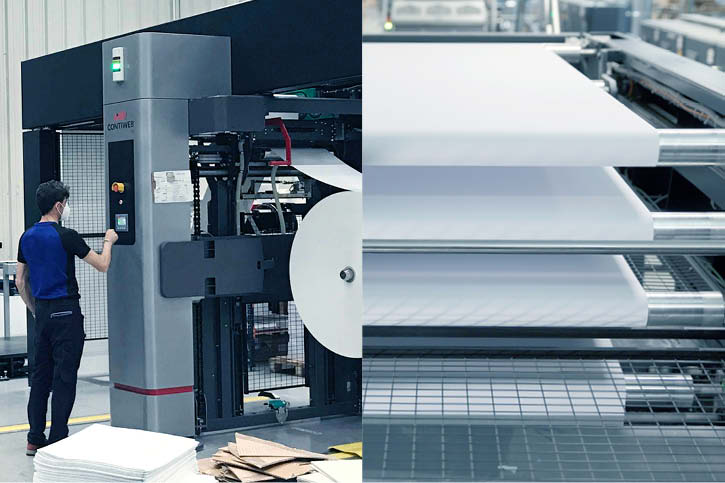

The CD-N is a horizontal zero-speed splicer featuring fully automatic splicing and a standard integrated infeed system.

The proven Contiweb zero-speed festoon design brings the running web and the new web to a halt during the splice cycle while the press is fed from the integrated festoon. Performing the splice at zero speed minimizes all dynamic forces on the web. The operation is therefore very forgiving of variations in splice preparation, such as operator skills and web quality. The splice can be made at all reel diameters, offering maximum flexibility for changing paper type or web width easily, including the smallest rest reels.

The lift arms of the Contiweb equipment can move up and down, allowing the reel to be loaded from the ground. This operation is ergonomic, and requires no lifting crane.

Also included as standard on the CD-N are high-specification festoon and guide rollers for maintaining optimum web tension control. Infeed functions and web guidance can optionally be controlled remotely through the central press/printer console. Remote diagnosis via VPN is also available.

Non-stop reel-to-reel production

For printshops running reel-to-reel workflows, Contiweb offers the CR-N Non-Stop Rewinder—the perfect match for the CD-N Non-Stop Unwinder. Together, they enable continuous production by auto-splicing reels at both the start and end of the press line. Splice preparation can be done at any point during the cycle, freeing up operator time and increasing flexibility. Partially printed reels can go directly to finishing, reducing turnaround times and manual handling.

Key benefits of the CD-N and CR-N combination:

• Fully automated reel changes—no press stops required

• Up to 25 minutes of extra production time per reel change cycle (unwinder + rewinder)

• Operator-friendly design with minimal manual tasks

Want to learn more about the CR-N?

Easy reel loading and splice preparation

Reel loading and splice preparation for automatic splicing using the Contiweb CD-N non-stop unwinder are quick and straightforward tasks that only take 2 minutes to complete. These tasks can be easily performed in a situation safe for the operator, even while production is ongoing. The operator's involvement is minimal and involves applying a linear adhesive tape for the straight-tape splice on the paper. The time required for splice preparation is limited to the actual preparation process itself.

Here, you can find a video demonstrating the reel loading and splice preparation process. The video demonstrates the overlap splice preparation. You can watch the butt splice preparation here.

Resources

Frequently Asked Questions

Below you find the answers to some commonly asked questions about this equipment.

Non-stop auto-splicing eliminates downtime caused by paper reel changes in web inkjet printing. This maximizes press output, improves efficiency, and lowers cost per print. At the same time, it reduces paper waste and frees operators to focus on higher-value tasks. The result: higher productivity and a smoother, more reliable workflow.

With a mono unwinder, every manual reel change can take around 15 minutes. If you need to change a reel every hour, this quickly adds up to a 25% loss in production capacity. The Contiweb CD-N Non-Stop Unwinder eliminates these costly interruptions. When the running reel is empty, it automatically splices the web to the new reel while production continues at full speed. The operator only needs to prepare the splice, a simple two-minute task that can be done at any convenient time during the splice cycle. For ergonomic loading, the CD-N is equipped with motorized lift arms that allow reels to be loaded safely from ground level.

Calculate your productivity gains with the Contiweb ROI Calculator

The Contiweb CD-N is an auto-splicer with two reel positions, allowing the next reel to be loaded and prepared while the first is running. As the expiring reel nears its end, a festoon (or accumulator) expands to build a paper buffer. The running reel is then stopped, and while the press is fed from the buffer, the splice is performed. The new reel accelerates to match press speed, ensuring production continues without interruption.

The Contiweb CD-N Non-Stop Unwinder is designed to eliminate downtime caused by reel changes. The CD-N has two reel positions, so while one reel is running, the next can be loaded and prepared in advance. Reel loading and splice preparation are safe, easy, ergonomic and take only two minutes. As the running reel nears its end, a festoon expands to create a paper buffer. The reel brought to a controlled stop, the expiring web is then cut, and the splice to the prepared reel is performed while both reels remain stationary. During this splice, the press is continuously fed from the buffer. Once complete, the new reel accelerates to press speed, ensuring seamless, uninterrupted production.

Watch how automatic splicing works and see how reel loading and splice preparation are done

A manual reel change on a mono unwinder takes around 15 minutes of lost production, even for trained and experienced operators. The press must slow down, stop, and later ramp back up, while the operator handles routine steps. If a reel is changed every hour, this downtime can reduce press capacity by 25% or more.

A manual reel change involves around 12 steps, including slowing down the press, cutting the web, unloading the empty core, loading and centering a new reel, taping, carefully threading the splice through the line at crawl speed to ensure it passes safely, and ramping the press back up to speed. Although the tasks are straightforward, they are disruptive and take the operator away from more valuable activities. Even with skilled operators, the process consumes around 15 minutes and leads to paper waste during restart. In busy production environments, these repeated interruptions add up to hours of lost output, higher substrate costs, and reduced overall efficiency.

Yes. The Contiweb CD-N Non-Stop Unwinder performs every reel change automatically while the press keeps running. It splices seamlessly to different paper types—whether grammage, coating, or reel width—without interruption.

Each manual reel change takes around 15 minutes, during which labor, energy, and paper are wasted. The CD-N eliminates this by executing the splice automatically while production continues. It can handle changes in grammage, coating, and reel width without issue, so operators save valuable time at every changeover. In addition, leftover reels can be processed down to the core, improving paper utilization and preventing unnecessary stock build-up. Together, these benefits ensure that auto-splicing remains highly valuable, even in short-run environments with frequent paper changes.

Contact Contiweb for more details

No. The Contiweb CD-N Non-Stop Unwinder is specifically designed for continuous-feed inkjet presses and ensures splices run safely through at full production speed. The system communicates with the press so the printheads retract at the right moment, avoiding any risk of contact.

The Contiweb CD-N combines exceptionally high splice quality with direct communication to the press. Every splice—whether overlap with a short tail or butt splice with no overlap—is produced with outstanding consistency and reliability. Before the splice reaches the print zone, the CD-N signals the press to retract the printheads briefly, preventing any risk of damage. Because the splice runs at full production speed, the loss of press time is negligible. By uniting this superior splice quality with synchronized press control, the CD-N ensures safe, reliable splicing and uninterrupted output, even at the highest web speeds.

Contact Contiweb to learn more about splice reliability in your press

The payback time for an auto-splicer depends on several factors, such as the price of the equipment, the amount of production lost during reel changes, the cost of wasted paper, and the operating costs that continue during downtime. When measured carefully, the impact of these losses is often higher than expected. Many customers recover the investment in a Contiweb CD-N in less than two years.

The return on investment for an auto-splicer depends on how often reels are changed and the costs that continue to accrue during downtime. Each manual reel change takes about 15 minutes, during which labor, energy, and press expenses accumulate, and additional paper waste occurs. When measured carefully, the total cost of lost production is often higher than expected. With a Contiweb CD-N, splicing is fully automatic, so operators spend less time on routine reel handling and more on valuable tasks. Because production continues without interruption, shift capacity increases. In peak periods, this higher output can reduce the need for overtime—or even remove the need for additional shifts.

Calculate your productivity gains with the Contiweb ROI Calculator

Trusted by

Trusted by

Would you like to know more?

If you are interested in Contiweb's non-stop unwindings solutions and you would like to know more, then please don't hesitate to contact us!

Your contact

Rob Bosman

Sales Director

+31 6 51 20 27 55

sales@contiweb.com