-

CR-N Non-Stop Rewinding Equipment

-

Automatic rewinding without production stop

-

Automatically change paper reels without production stop

Keep digital print jobs moving continuously

Benefits

- Save production and labor hours: Non-stop winding eliminates manual reel changes that cause downtime, significantly increasing press uptime.

- Increased operator flexibility: Splice preparation can be done at any convenient time during production—allowing operators to focus on other tasks.

- Fast and simple splice preparation: Preparing a splice takes just two minutes.

- Exceptional splice reliability: Achieve consistent splice performance of 99.8% or higher.

- Versatile splicing options: Splice to reels with different web widths, coatings, and weights—ideal for short runs and fast job changes.

- On-demand splicing: Splices can be made on the fly without stopping production. When different finishing is required for jobs using the same paper, the CR-N non-stop rewinder can rewind onto separate reels.

- Smart integration with your press: If your press supports it, Contiweb equipment can signal the press ahead of a splice—allowing print heads to lift in time. It can even detect splices made by the paper mill.

- Ergonomic reel loading: Motorized lift arms move up and down so reels can be loaded from ground level—no crane needed.

- Additional advantages include fewer errors during splice preparation, less risk of web loss due to time pressure, reduced paper waste, smoother startups, and energy savings through faster changeovers.

Features

- Horizontal festoon for zero-speed splicing.

- Lap splice as standard; butt splice available as an option.

- Motorized arms for lifting reels on and off the loading platform.

- No reel shafts required.

- Compatible with all web inkjet presses.

- Supports paper weights up to 350 g/m² (18 pt).

- Maximum winding speed: 330 m/min (1080 ft/min).

- CR-N non-stop rewinder available in 22" (560 mm), 42" (1100 mm), and 61" (1550 mm) versions.

CR-N non-stop rewinder

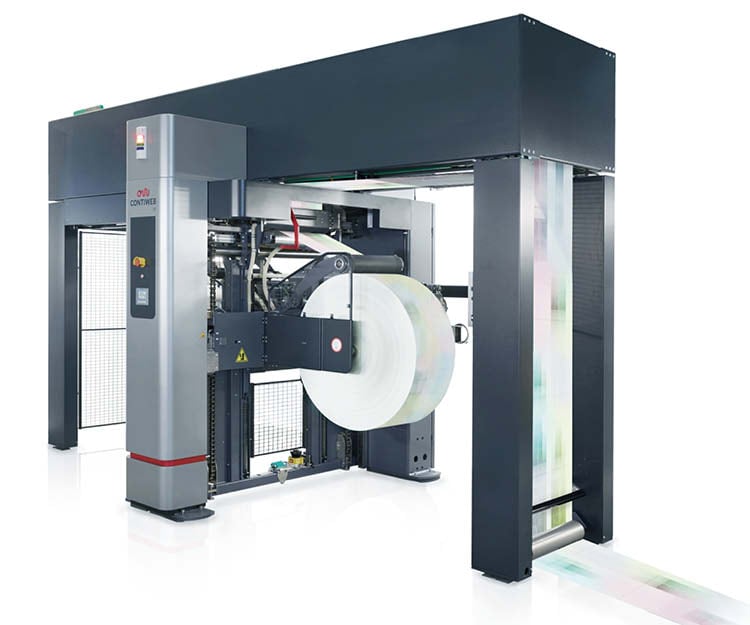

The CR-N is a fully automatic non-stop rewinder designed for reel-to-reel print production. It delivers perfectly rewound reels without interrupting production for reel changes.

When a printed paper reel is nearly full, the CR-N’s festoon temporarily stores printed paper, allowing the system to stop both the full and empty reels, cut the web, and splice it seamlessly to a new core. This enables continuous production—no need to halt the press to remove a full reel or load an empty one.

With the CR-N, splices can be made on the fly. Jobs that use the same paper but require different finishing can be rewound onto separate reels without downtime.

The rewinder’s shafts are removable and must be inserted into the core of the new reel. Motorized arms move the shafts up and down, enabling easy reel loading and unloading directly from the floor—no crane required.

An optional slitter is available before the splice point. This allows the web to be slit into ribbons of variable widths during production, with uninterrupted splicing and reel changes. Printers can transition seamlessly between reels while slitting, maximizing flexibility and uptime.

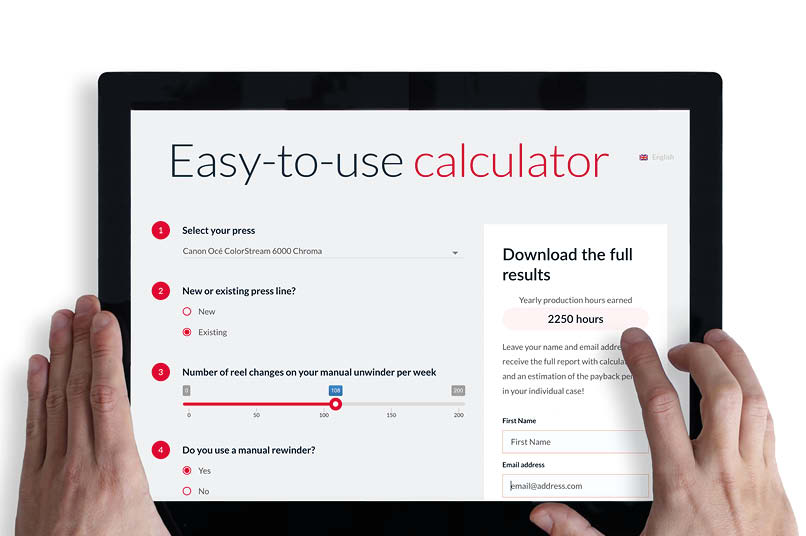

Short payback period

By eliminating an enormous number of lost production hours when using manual winding equipment, non-stop winding equipment normally pays for itself very quickly.

Use our easy calculator tool for an indication of the payback period and determine whether you can benefit from non-stop winding.

Trusted by

Frequently Asked Questions

Below you find the answers to some commonly asked questions about this equipment.

There are situations in which printing companies opt to rewind certain printed jobs instead of finishing them inline. Several factors contribute to this decision. One such factor is when the finishing process is outsourced to an external company. In these cases, rewinding the printed reel proves to be a practical choice. By sending the reel to an external finishing provider, better coordination and control can be achieved over the finishing process. This approach ensures that the external company receives a neatly wound reel, facilitating their handling and enabling them to perform specific finishing tasks with ease.

Another reason for choosing to rewind printed jobs is workflow optimization. At times, the finishing line may be occupied with other ongoing jobs or require specific setup configurations. By rewinding the printed reels, they can be temporarily stored and queued for finishing at a more opportune time. This flexibility in the workflow significantly enhances overall productivity, reduces bottlenecks, and ensures a seamless production process.

When utilizing a Contiweb CR-N non-stop rewinder in combination with a Contiweb CD-N non-stop unwinder, printers gain several additional benefits, including the capability of executing a coordinated splice. This refers to the process of making a splice at the exact same location when the paper reel is wound by the CR-N non-stop rewinder as the splice made at the beginning of the process by the CD-N non-stop unwinder. These splices align perfectly on top of each other. This synchronization is made possible due to the zero speed technology and paper buffer of the CR-N non-stop rewinder, which provides enhanced control over the splicing moment. The advantages of a coordinated splice include reduced waste and the assurance of having a printed roll of paper that matches the unprinted roll precisely.

The CR-N non-stop rewinder offers the option to be equipped with either shear or crush slitters for cutting purposes.

Shear slitting involves the use of sharp circular knives that move against the paper and cut through it. Shear slitting is known for producing clean and precise cuts, making it suitable for paper up to 350 g/m².

Crush slitting employs a sharp cut knives that press against a hardened roller. The cuts may be slightly less precise compared to shear slitting. However, crush slitting offers certain advantages. It allows for more frequent cuts, with a minimum distance between cuts. Additionally, during production, the position of the cuts can be manually adjusted, and the cut can be combined with perforation if desired.

The operator must insert a core into the CR-N non-stop rewinder to which a small piece of paper is attached, sufficient to reach the splice head. There, the adhesive tape should be stuck so that the CR-N non-stop rewinder can connect the empty reel to the printed paper coming out of the printing press.

The Contiweb CR-N non-stop auto splicer has lift arms that can move up and down. This operation is ergonomic, and requires no lifting crane. Also no reel shafts are required (when slitting is not selected).

The Contiweb CR-N non-stop auto splicer allows you to splice over to papers of different web widths, coatings and weights. This is very useful for short, fast-changing jobs.

The Contiweb CR-N non-stop auto splicer makes an overlap splice when joining two reels of paper.

The Contiweb CR-N non-stop auto splicer can handle paper reels with a diameter of up to 1,520 mm (60 inches) and a maximum weight of 1,600 kg.

Spare parts for Contiweb non-stop auto splicers are conveniently available in the Contiweb Parts Webshop. Sign up for an account and gain free access to Contiweb machine manuals and parts books, saving you valuable time by filtering your search for specific machine parts.

Plus, explore our Uptime Kits, specially curated with essential components to minimize downtime in the event of breakdowns, ensuring you have the necessary parts readily available in your own facility. Streamline your maintenance and keep your operations running smoothly with Contiweb.

Trusted by

Would you like to know more?

If you are interested in Contiweb's non-stop unwindings solutions and you would like to know more, then please don't hesitate to contact us!

Sales contact

Rob Bosman

Sales Director

+31 6 51 20 27 55

sales@contiweb.com