4 common post-drying problems in web inkjet

In an earlier blog, Rob Bosman explained why remoistening is important in web inkjet printing. Here, we take a closer look at the problems that might occur if this key step is missed.

There are various problems that arise after drying a digitally printed substrate – to put a number on it, there are four issues that commonly affect the quality of digitally printed products. The high temperatures generated during drying result in the loss of moisture and invariably, the printed matter diminishes in quality. Here we explore those issues and, more importantly, what can be done to resolve them.

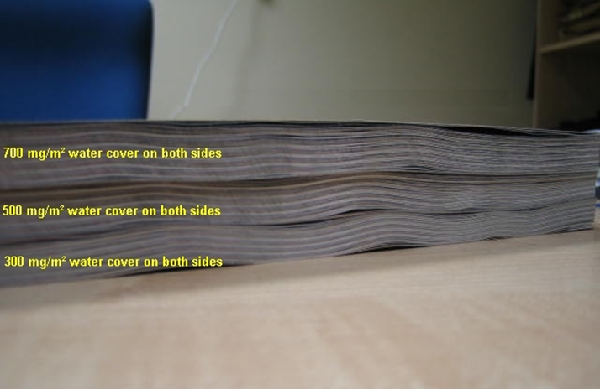

Waviness

One key problem is the loss of flatness of signatures, which occurs as a result of the moisture absorption of the signatures after printing. As the edges of the paper are exposed to the atmosphere, they reabsorb moisture and thicken – distorting the edges and causing a wavy effect and making it difficult for signatures to lie flat.

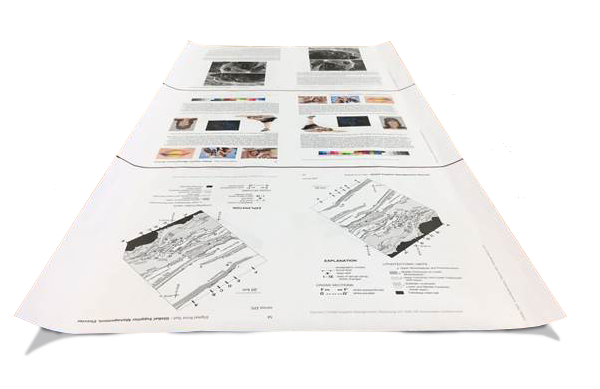

Curling

Curling means exactly what it sounds like! Simply put, the edges of the printed material curl up or down. In general, the web curls to the side where the most water is applied, in the form of ink. This occurs because the paper is first printed on one side, and then dried, and then printed on the other side and dried. Curling can be easily avoided by remoistening each side of the paper independently, tailored to suit the ink levels used on each side.

Broken folds

As you’d expect, dehydrated paper is brittle and can therefore break faster in the fold. This is one of the more simple and obvious indications of a lack of moisture.

Growth of cut books

When booklets are printed, dried and bound together with an accompanying cover that has been printed sheetfed offset, there’s frequently a problem with growth. Both booklet signatures and covers are assembled and cut a short while after printing. Over time, the dried signatures will absorb moisture from the environment and expand width-wise. This is because paper is hygroscopic – it seeks to balance its own humidity to that of the surrounding environment, and when the paper fibres absorb moisture, they thicken more than they lengthen – expanding perpendicularly to the direction of the fibres. But where the covers are not dried as a part of the printing process, they don’t need to absorb moisture, so there’s no expansion. The resulting cover no longer fits neatly onto the signature and is in no way ideal on either a practical or an aesthetic level.

The remoistening solution

Undercutting the perception that remoistening isn’t required in digital inkjet printing, it’s the solution to all of the problems we’ve outlined in this blog. Contiweb’s Digital Fluid Applicator (DFA) uses tap water and surfactant to provide precise remoistening, that can be applied independently to each side of the web – resolving many of the issues inherent to drying and positively impacting the user experience. The DFA is also compatible with digital web presses from all well-known manufacturers, such as HP, Canon, Océ, Screen and Ricoh.