-

Contiweb

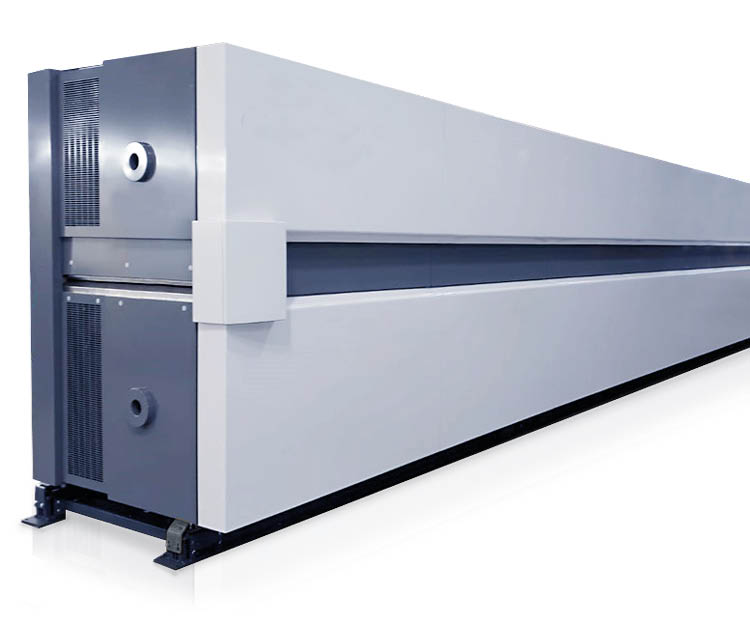

Ecodry hot air dryer

-

For narrow web width offset presses

-

Integrated afterburner and cooling zone

Ecodry hot-air dryer for narrow web width

The Ecodry hot-air web offset dryer covers the narrow web (16 page) market, with printing presses already equipped with conventional chill stands. This dryer has an integrated afterburner, which incinerates the solvents from the ink to produce clean exhaust air. The thermal energy gained from burning the solvents is effectively being re-used in the heating process. The solvent concentration control system in the dryer reduces the total air flow through the dryer to a minimum. The result is a significant reduction of the gas consumption.

The Ecodry dryer has an integrated cooling zone, which reduces the web outlet temperature by approximately 40°C (72°F). During production stops the dryer is kept at stand by temperature for quick restart.

Benefits

- High quality and productivity.

- Efficient way of drying at low temperature.

- Automatically optimized temperature.

- Enhanced web control.

- Low gas consumption.

- Less web breaks.

Features

- The Ecodry dryer is supplied as one complete unit.

- It complies with the latest standards EN 1539, NFPA 86 and the directives of the VDI.

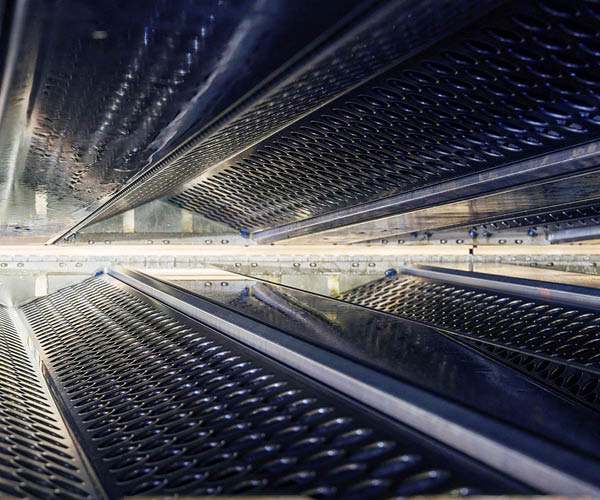

- Three temperature zones: heating zone, drying zone and cooling zone.

- The air circulation system provides a high air volume to the patented

- "Crossjet" air nozzle bars.

- Web temperature control by infrared camera, located between drying zone and cooling zone.

- Two afterburner installations with heat exchangers and frequency-controlled fans.

- Door sensors for safety.

- VPN connection for remote diagnosis system.

- Gas type different from natural gas on request.

Frequently Asked Questions

Below you find the answers to some commonly asked questions about this equipment.

The Contiweb hot air dryers offer an innovative solution for recycling energy from ink solvents to fuel combustion and maintain dryer temperatures. As the air containing evaporated solvents reaches the end of the dryer section, it is directed into integrated combustion chambers for incineration. The exhaust air is then thoroughly cleaned and recirculated back into the dryer section, effectively reusing the existing heat.

One notable advantage of the Contiweb drying process, which incorporates the integrated afterburner, is its significant reduction in energy consumption compared to traditional systems. Depending on factors such as ink coverage and speed, the integrated afterburner can contribute to significant energy savings. This efficiency improvement benefits both cost savings and environmental sustainability.

If you are interested in exploring the possibilities for reducing gas consumption and achieving cost savings with your existing dryer, Contiweb's Gas Reduction Enhancement program offers a viable solution.

Contiweb dryers offer the advantage of being equipped with frequency drives that allow continuous adjustment of fan speeds, ranging from 0 to 100%. In contrast, fans in conventional dryers typically operate at fixed speeds of either 50% or 100% of their nominal speed, often resulting in unnecessary energy consumption. By utilizing the fully variable speed capabilities of frequency drives, the power consumption of Contiweb dryers can be significantly reduced by up to 50%. This not only leads to cost savings but also provides the added benefit of extending the lifespan of motors, motor bearings, V-belts, and fans.

Recognizing that not all printing companies are ready to invest in a new energy-efficient dryer, Contiweb offers an appealing solution known as the Electrical Power Reduction enhancement. This enhancement allows printing companies to achieve substantial electricity consumption savings with their existing dryers.

Contiweb hot air dryers offer a range of benefits, including significant reductions in gas and electricity consumption, as well as lower CO2 emissions.

Through the post-combustion of solvents, Contiweb dryers can achieve remarkable gas consumption reductions of up to 70% compared to conventional dryers. This represents a substantial decrease in resource usage and associated costs. Furthermore, the implementation of variable frequency drives to power the dryer fans allows for electricity consumption reductions of up to 50%. This not only contributes to cost savings but also has a positive impact on CO2 emissions, promoting environmental sustainability. You can get an indication of your potential savings with the Sustainable Savings Estimator.

It's important to note that the extent of cost savings and CO2 reduction achieved will vary depending on factors such as ink coverage and speed. To obtain a precise calculation tailored to your specific requirements, please reach out to the Contiweb sales department. They possess the expertise and knowledge to assist you in determining the potential benefits and conducting a comprehensive cost analysis.

Many governments around the world offer subsidies and incentives to businesses that invest in capital goods aimed at reducing their carbon footprint and promoting sustainability. These subsidies are part of broader environmental and climate change initiatives to encourage businesses to adopt cleaner technologies and practices. The availability and nature of these subsidies can vary depending on the country and region.

Government agencies, environmental departments, or industry associations can provide information on available programs and eligibility criteria. Consulting with sustainability experts or financial advisors can also help navigate the subsidy landscape and identify the most relevant opportunities for reducing the carbon footprint through capital goods investments.

Contiweb offers a comprehensive range of service programs for its dryers to ensure optimal customer support and long-term equipment performance. When you choose Contiweb equipment, you enter into a lasting partnership built on mutual commitment, enabling continuity in the Heat Set Web Offset market. Our Service Support Agreements are designed based on these fundamental principles.

We provide four distinct packages that cater to various needs and maintenance philosophies. The key objectives of our service programs are as follows:

- Ensure top level customer service

- Increase uptime

- Safeguard low operating costs

- Ensure compliance and sustainability

- Keep maintenance costs predictable and competitive

Spare parts for Contiweb dryers are conveniently available in the Contiweb Parts Webshop. Sign up for an account and gain free access to Contiweb machine manuals and parts books, saving you valuable time by filtering your search for specific machine parts.

Plus, explore our Uptime Kits, specially curated with essential components to minimize downtime in the event of breakdowns, ensuring you have the necessary parts readily available in your own facility. Streamline your maintenance and keep your operations running smoothly with Contiweb.

In today's uncertain economic climate, investing in new capital equipment can pose challenges for many companies. Considering used machines can be an intriguing alternative.

Contiweb recognizes this need and maintains a dynamic inventory of used dryers. These machines undergo meticulous inspection, repairs, and, if desired, upgrades to ensure their quality and reliability. When a used piece of equipment leaves Contiweb's facilities, it is designated as Certified Pre-Owned, providing customers with added confidence. Furthermore, Contiweb offers a 6-month warranty with each Certified Pre-Owned machine.

Would you like to know more?

If you would like to know more about the Contiweb Ecodry hot air dryer for web offset applications, then please don't hesitate to contact us!

Sales contact

Rob Bosman

Sales Director

+31 485 597 111

sales@contiweb.com