Value Activity Mapping in Web Inkjet Printing

Printing is a fairly straightforward business. You buy paper, apply ink and do some finishing. If you can sell at a price that covers your costs – ideally providing a margin, then you have a successful business. Of course there is a lot more to it than that, but it is fundamentally a straightforward business model, print and convert to add value. Many print companies have developed niches where they can apply their expertise – maybe in graphic design, some sophisticated finishing or understanding needs in a particular vertical where they know the regulatory framework and help customers meet requirements in different countries.

This makes printing extremely competitive. While the number of print-for-profit sites is dropping as demand for some products falls, exacerbated by COVID-19 stressing companies with weak balance sheets and reserves there is still overcapacity across the world for publication, advertising and commercial printing. This makes efficiency within a print shop ever more important. New technology succeeds when it can save time and take costs out, and that has been the strategy for many companies able to invest in modern print or finishing equipment, with the associated workflow. A critical success factor then becomes how companies use these production assets.

Maximise the productive time of a press

Digital presses only generate revenue when they are printing saleable product. The more they run the higher this potential revenue and the lower the total cost of ownership, because the capital cost is amortised across higher print volume. So it makes sense to maximise the productive time of a machine, and to try to eliminate all factors that prevent the machine printing at full speed. A good technique that is widely employed as part of a Lean Manufacturing approach is Value Activity Mapping. This basically tracks what actually happens on a machine across a shift. These actions are recorded over time and categorised into those that customers are willing to pay for, and all others.

Value Activity Mapping

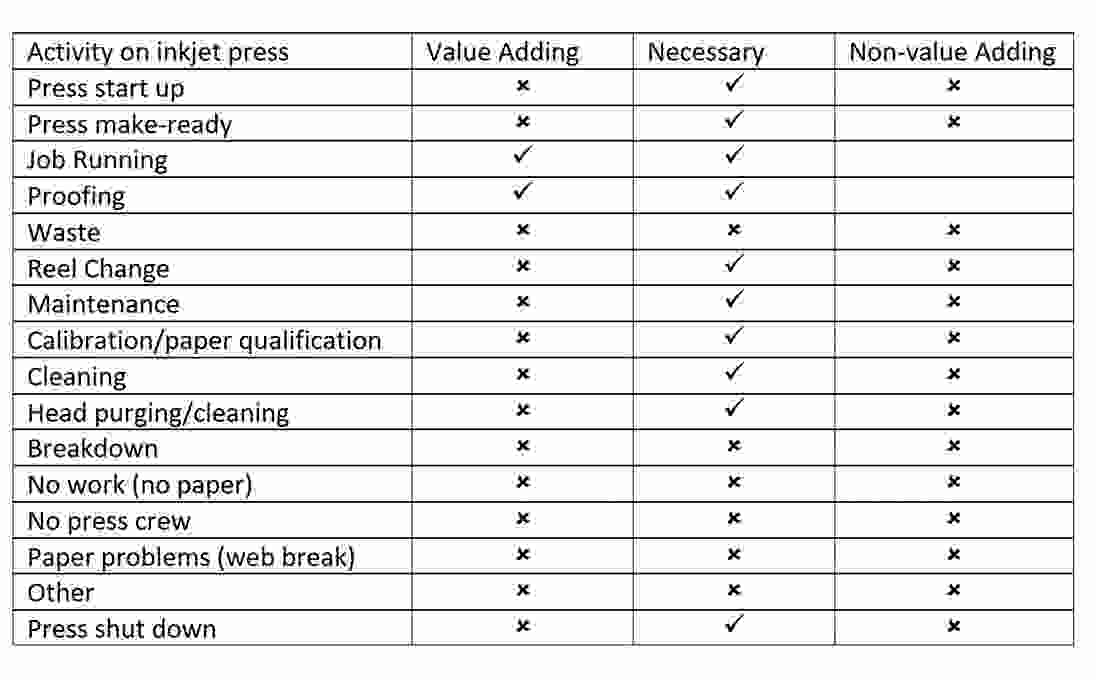

For a printing machine the customer will pay for good quality output (and some may be prepared to buy machine time for proofing or prototyping), but that is all. Everything else is a direct cost to the printer. Value Activity Mapping asks the question: “Why do these non valuable things?”. Identify them and don’t do them. The table categorises the activities that most inkjet press users will recognise.

When this is quantified with the time actually consumed over a number of weeks it is informative to realise the amount of time spent in non-value adding activities. Customers do not buy make-readies, and they do not buy waste – so why do companies spend time doing these things? The idea of value activity mapping is to determine what customers will pay for and make sure that this is what the machine spends its time on, an eliminate the other activities. Of course, as with any piece of production equipment, there may be some things required for the machine to perform. At the start of a week the press should be switched on (many companies programme an automated start up so the machine is ready to print when the operator commences her shift), similarly it needs to be shut down in accordance to the operating procedure which may need an operator to check, so time is lost. Paper testing and qualification may allow a lower-cost substrate, calibration is necessary to ensure optimal quality. Maintenance and cleaning are vital for all inkjet machines, but they do not directly add value to the customer. Putting a new reel onto the press is necessary but the customer will not pay for this as a line item in an invoice.

Eliminate non-value adding activities

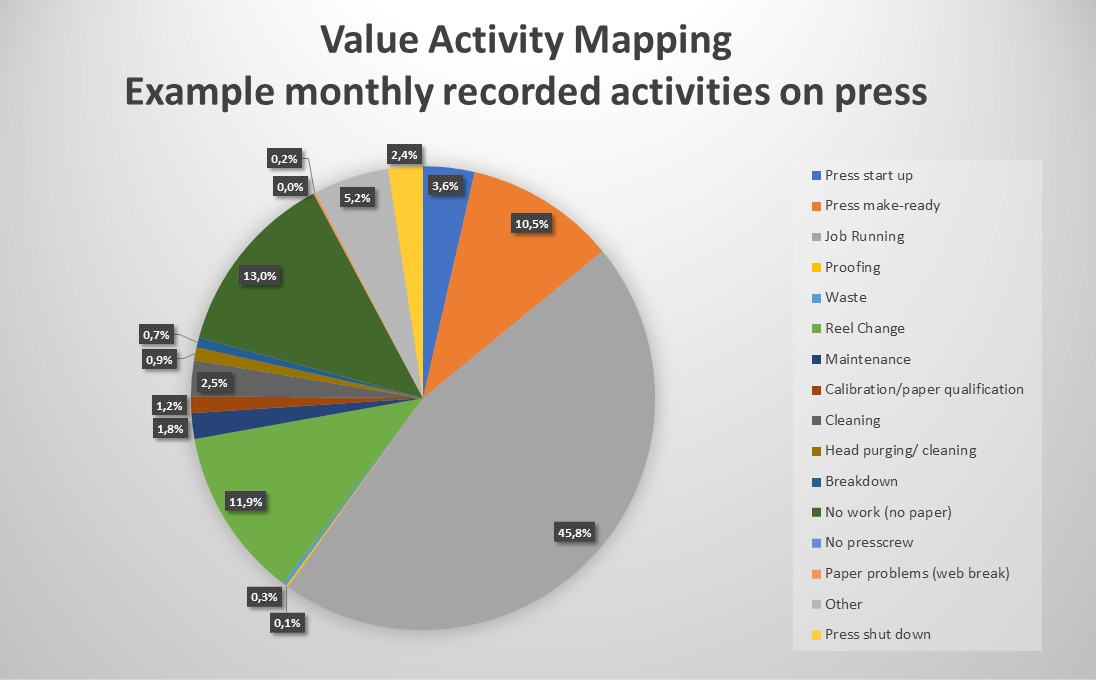

After a suitable (representative) period of recording, the results will look similar to the pie chart above. This is for a double-day shift pattern, measuring what happened during the planned hours on press. In this (fictional) case the customer can see the issues with no work and other and plan accordingly, while the production team can take action on the start up and shutdown time, breakdown, make-ready and time spent on reel changes. Speeding up these necessary tasks will release capacity on the machine, improving the amount of time available to add-value for the customer, to the benefit of the inkjet printing company. Eliminate these non-value adding activities to boost press uptime and capacity.