The Role of Fabric Sleeves in Resolving Post-Drying Problems

Continuous feed inkjet printing has made remarkable strides in the printing industry. Nevertheless, the high temperatures necessary for drying water-based inks have introduced new challenges to digital printers. Common post-drying issues, such as wavy paper and curling paper edges, can disrupt the production process, resulting in downtime and compromised print quality. In this blog, we explore how fabric sleeves play a pivotal role in mitigating them.

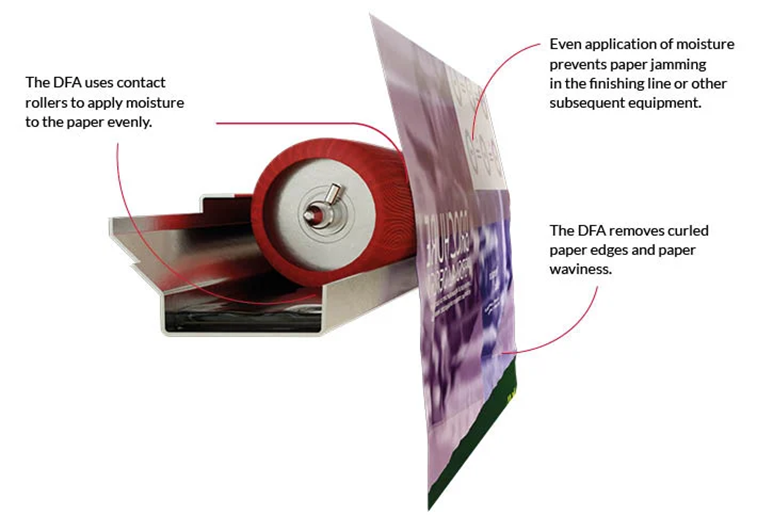

To address the aforementioned post-drying problems, remoistening the printed and dried material is a recognized solution. However, it is vital to ensure the uniform distribution of a precisely set amount of moisture across the paper web during this process. Inadequate moisture coverage can still lead to quality issues.

The Contiweb Digital Fluid Applicator tackles this challenge. This innovative system features a closed-loop control mechanism that ensures a precise and predetermined amount of moisture is provided to the fabric sleeves. These sleeves, in turn, apply the moisture evenly onto the paper web, ensuring optimal results.

Unique Characteristics of Fabric Sleeves

At the heart of Contiweb's Digital Fluid Applicator lie two rollers (one roller per side of the paper) surrounded by a carefully crafted fabric sleeve. These fabric sleeves feature a distinctive engraved pattern on their surface, comprising precisely sized and spaced cells. This intricate pattern forms a controlled system for storing and releasing moisture, facilitating exceptional fluid distribution across the paper web and ensuring uniform coverage.

Textile sleeves exhibit inherent resilience and compression properties. When pressure is applied due to the unevenness of the printed paper, the fabric sleeve undergoes a slight deformation. This adaptability enables the sleeve to maintain a consistent contact surface with the paper, ensuring reliable fluid transfer. By accommodating variations in the paper surface, textile sleeves contribute to the consistent and accurate application of fluid, ultimately enhancing overall printing performance.

The Contiweb Digital Fluid Applicator requires minimal maintenance due to the utilization of tap water and, if desired, pure silicone oil instead of osmosis water and silicone emulsion. The fabric sleeves possess exceptional qualities that contribute to significantly reducing contamination levels.

Proactive Monitoring and Easy Replacement

While fabric sleeves offer precise and uniform fluid coverage on paper, they are not immune to wear. Various factors, such as print volume, print speed, web tension and substrate characteristics, influence the lifespan of fabric sleeves. Some printers may utilize the same fabric sleeves for several months, while others may need to replace sleeves more frequently.

Replacing the fabric sleeves is a straightforward procedure. The roller containing the worn sleeve is detached from the Digital Fluid Applicator, the worn sleeve is cut open and removed from the roller. The new fabric sleeve is then shrunk tightly around the roller with hot water and the roller is reinstalled into the machine. As the roller rotates through the pan and becomes moistened, it is ready to resume its function. Printers who do not want to lose any production time, can prepare an extra set of rolls with new sleeves.

Reliable solution

Post-drying problems in webfed inkjet printing, such as wavy paper and curling edges, can disrupt the printing process and compromise print quality. However, the incorporation of fabric sleeves in Contiweb's Digital Fluid Applicator provides a reliable solution. By ensuring even moisture distribution through their engraved pattern and exhibiting resilience and adaptability, fabric sleeves contribute to consistent and high-quality printing.