Unveiling the Hidden Advantages of Contiweb Non-Stop Unwinders

While it is widely recognized that non-stop auto splicers can significantly enhance the productivity of your web inkjet printing press, the decision to invest in them should not be solely based on the gained production hours. Contiweb non-stop unwinders and rewinders offer a range of additional advantages that can greatly improve press operators’ workflow compared to manual reel changing.

In this blog post, we explore these hidden benefits, providing insights into their significance and value.

Effortless Reel Handling and Enhanced Safety

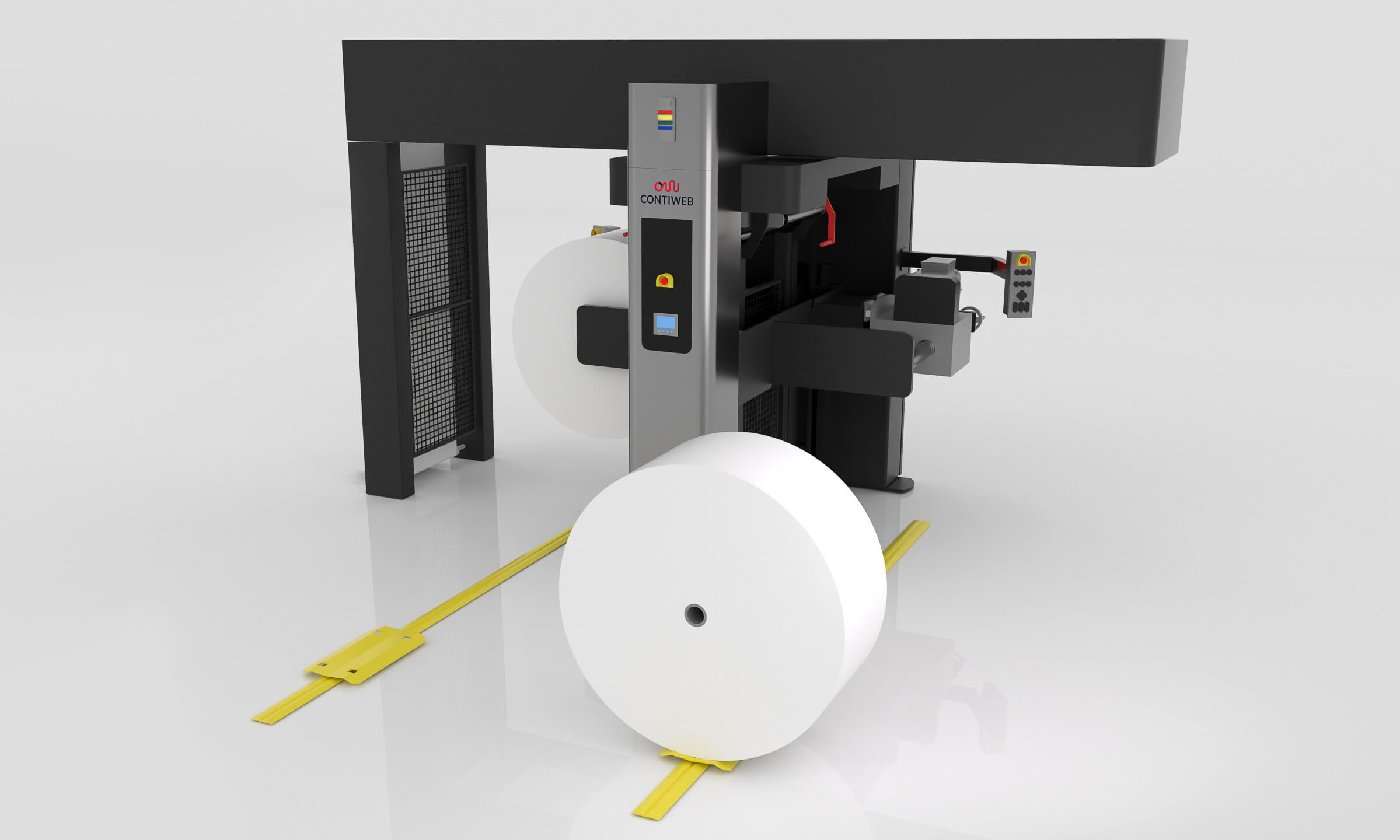

Contiweb's CD-N non-stop unwinder simplifies the initial step of the printing process, which involves unwrapping and unrolling the paper roll. With lift arms that elevate the roll off the ground (or off a trolley or pallet), operators can comfortably remove the packaging from the roll at an ergonomic height, eliminating the need to bend down. This streamlined process minimizes paper loss, as every millimeter counts when it comes to expensive paper. Moreover, it maximizes operational efficiency, ensuring a seamless and productive workflow.

In addition, based on decades of experience with paper reel handling, Contiweb has developed tools for the operator that further ease the process. Contiweb's floor track transport system facilitates the positioning and placement of the wrapped paper roll onto the CD-N non-stop unwinder's lift arm without the need for awkward maneuvers. This further enhances the convenience and ease of reel handling.

Contiweb's floor track system for paper reels

Furthermore, the CD-N unwinder creates an extremely safe working environment for press operators, without loss of accessibility. Approved by the German BG and meeting the highest safety requirements, the machine holds the prestigious BG approval, also known as "BG-Prüfzertifikat" or "BG-Zertifikat." This certification assures businesses that the CD-N unwinder has undergone comprehensive safety assessments, adhering to the required safety standards set by the respective Berufsgenossenschaft. By complying with applicable safety regulations, the CD-N reduces the risk of accidents and ensures the utmost protection of workers.

Reliable Splicing for Continuous Production

Uninterrupted production is crucial for press operators, and the CD-N non-stop unwinder guarantees the quality and consistency of splicing. With a measured splice reliability of over 99.7%, independent of operator skills, the CD-N eliminates the concern of paper web breaks. These breaks can lead to prolonged production downtimes and significant challenges. By allowing independent splicing regardless of press speed, paper diameter, web width, grammage, and grade, maintaining the 99.7% splice reliability, the CD-N ensures seamless transitions between paper rolls, enabling operators to maintain continuous production without disruptions. With certainty in the quality of splices, press operators can focus on core tasks, maximize efficiency, and minimize downtime.

Easy Operation and Adaptability

In addition to its remarkable functionality, the CD-N non-stop unwinder boasts an intuitive design that ensures a pleasant working experience for press operators. The machine's ease of operation requires only a short training session, making it convenient, which is important, especially during times of staff shortages. This adaptability and user-friendliness allow operators to quickly familiarize themselves with the CD-N unwinder, ensuring a smooth transition and minimal downtime.

The CDN's ease of operation requires only a short training session, making it convenient, which is important, especially during times of staff shortages.

Remote Monitoring and Diagnostics

Contiweb has a long history In the heat set web offset industry, in which we serve customers around the world who produce 24/7 and have tight deadlines. Unexpected downtime can have huge financial consequences for such clients and lead to reputational damage. Fast response times and resolution of problems are then critical so that the customer can resume production as soon as possible.

Contiweb's 24/7 Remote Tech Support teams in the Netherlands and the United States, consisting of experienced and trained product specialists, are able to solve most problems remotely without the need for an engineer to come on-site. Thus saving valuable time and costs. The prerequisite for this, however, is that the team can log into the Contiweb machines via a VPN connection and thus analyze what is going on.

Analysis of the data also provides us with benchmarks on the performance of the machines at customer sites. We can proactively and openly inform customers about the performance of their machines against these benchmarks, and advise how they can realize the full potential of their equipment. The vast amount of data we have collected on our machines over the years gives us extensive knowledge about the performance and capabilities.

Conclusion

With 2,500 splicers sold over the years, Contiweb has established itself as a trusted industry leader with extensive experience and unparalleled know-how. Investing in Contiweb non-stop unwinders unlocks a range of benefits beyond increased production hours. These advantages, including streamlined unwinding processes, enhanced operator safety, reliable splicing, effortless operation, and remote monitoring and diagnostics, improve press operators' workflow and deliver exceptional results. With BG approval and a commitment to high-quality equipment, Contiweb empowers businesses to optimize efficiency, reduce downtime, and cultivate a safe and productive working environment. Embrace the hidden benefits of Contiweb non-stop unwinders to unlock the full potential of your web inkjet printing press.