Dryer Replacement: Crunching the Cost-Benefit Numbers

For heat-set web offset printing companies, the purchase of a new hot air dryer represents a significant investment. However, it is crucial to understand that this investment yields significant long-term benefits that more than compensate for the initial costs. In this analysis, we delve into the fundamental advantages that need to be factored into a cost-benefit assessment, highlighting the financial, operational, and socio-economic aspects for printing businesses considering a dryer replacement.

Significantly lower costs for repairs and replacement of parts

Hot air dryers for the heat-set web offset industry are designed for intensive and long-term use. However, as they age, the regularity of repairs, maintenance, and replacement of parts escalate, ultimately leading to heightened operational costs.

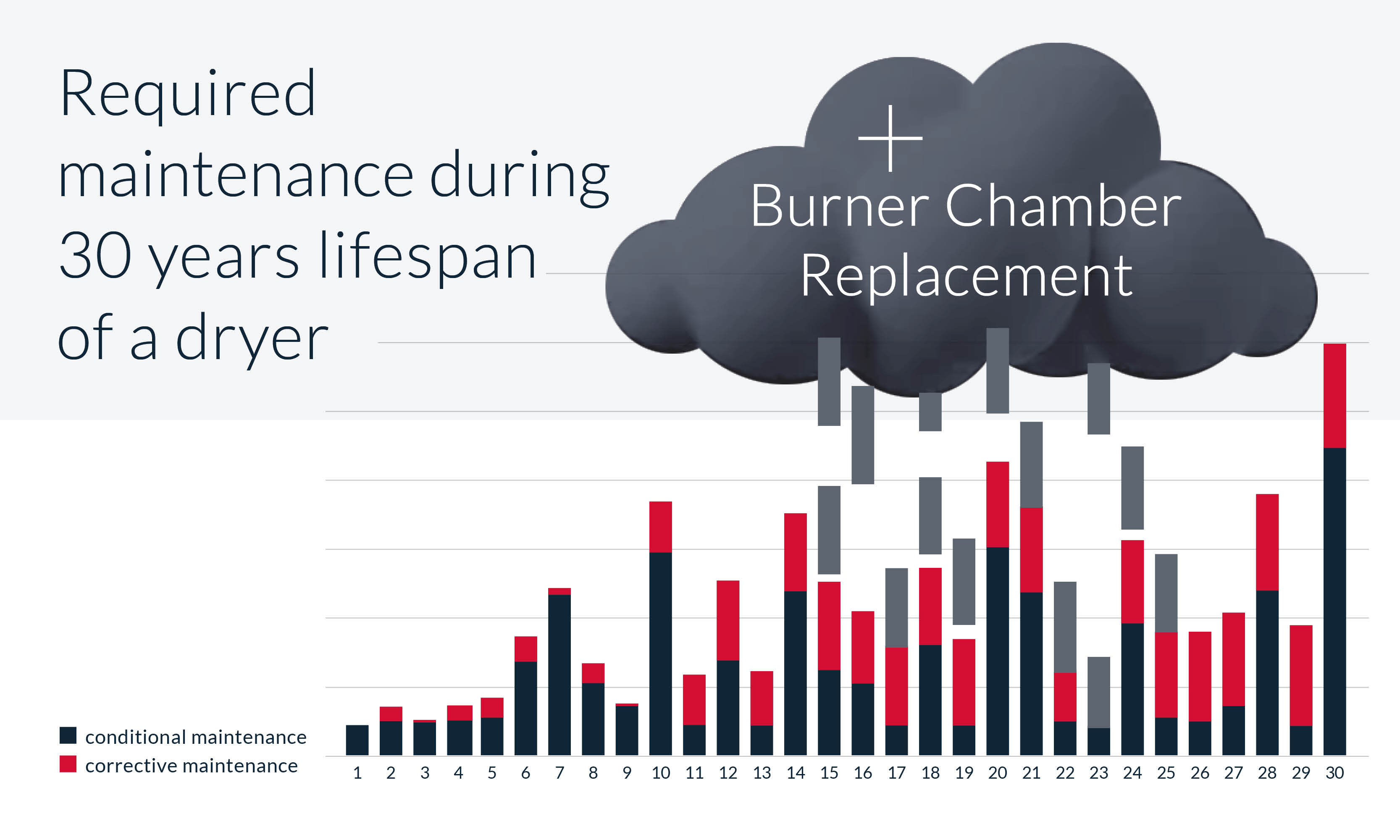

The graph above shows the increase in conditional and corrective maintenance over the lifetime of a hot air dryer. Depending on the use of the dryer, the burner chambers need to be replaced after approximately 15-25 years, which is a substantial investment.

The graph above shows the increase in conditional and corrective maintenance over the lifetime of a hot air dryer. Depending on the use of the dryer, the burner chambers need to be replaced after approximately 15-25 years, which is a substantial investment.

One of the critical concerns arising from the aging process is the unavailability of specific parts, potentially leading to prolonged downtimes and significant production delays. In some cases, the procurement of obsolete parts from the secondary market becomes the only viable option, albeit at a substantially inflated cost.

Additional costs may arise if lost production hours need to be made up by having employees work overtime. If the production costs of a heat-set web offset press are €1,500 per hour, any downtime will be particularly painful.

With the acquisition of a new dryer, businesses can enjoy a significant reduction in repair expenses and enhanced reliability, owing to the state-of-the-art technology and a comprehensive warranty package that provides peace of mind.

Huge reduction in gas and electricity consumption

Cost savings will also be realized in terms of gas consumption. The consumption of a modern dryer is in many cases significantly lower than that of an old dryer. By replacing it with a new dryer with integrated afterburning, the thermal energy obtained by burning the solvents from inks is effectively reused in the heating process of the dryer. The latest generation dryers are many times more efficient in this regard than the old models.

There are also benefits in terms of electricity. The fans of new dryers (a 4-section dryer has 8 fans) are equipped with state-of-the-art motors that can control and vary the speed of the fans much more precisely. This results in a significant saving in electricity consumption. An additional advantage is that the motors, V-belts, and fans have a considerably longer lifespan as a result. Moreover, the peak load during startup is lower, which can lead to even more savings (depending on the electricity contract).

Contiweb has made calculations of energy savings for many printing companies. These savings often amount to hundreds of thousands of Euros per year. Below is an example calculation in which an old generation dryer with integrated afterburning is replaced by a latest generation Contiweb dryer with integrated afterburning.

Roularta Printing invests in three new Contiweb dryers

The practical realization of these savings is exemplified by Roularta Printing, showcasing the tangible benefits achievable in real-world scenarios. This Belgian printing company has a pioneering role in sustainability in the printing industry and aims to be climate neutral by 2040. Recognizing the considerable potential for improvement in the drying process, the management team at Roularta made the strategic decision to invest in three state-of-the-art Contiweb dryers.

The installation of the new dryers resulted in a 50% reduction in gas consumption, a 30% reduction in electricity, and a 14% reduction in CO2 emissions. The reduction in CO2 emissions leads to a direct saving in the form of a lower CO2 tax.

Toward Sustainable Operations

The commitment to sustainability has become a paramount focus for organizations across various industries, and the printing sector is no exception. With the European Union aiming to be climate neutral by 2050, companies are increasingly encouraged to become more environmentally conscious. Notably, the heat-set web offset technology contributes significantly to overall CO2 emissions and fossil fuel consumption. Consequently, the decision to invest in new dryers that boast superior energy efficiency presents a compelling opportunity for businesses to align themselves with the broader sustainability goals.

Furthermore, government initiatives providing subsidies for companies investing in eco-friendly production equipment serve as an additional catalyst, facilitating a fast return on investment for forward-thinking printing companies.

Proactive control of energy consumption

We understand that your employees cannot dedicate their entire day to monitor the gas and electricity usage of your dryer. Their primary focus is typically on ensuring timely delivery of print orders and maintaining the desired print quality. Therefore, Contiweb has introduced an innovative remote monitoring system.

Through a secure VPN connection, the Remote Tech Support team at Contiweb has real-time insights into the performance of the company's dryer systems. Using a comprehensive database encompassing data from numerous dryers globally accumulated over several years, Contiweb can proactively guide and inform clients based on industry benchmarks, enabling them to optimize their energy consumption effectively.

For customers with a Service Support Agreement, all important data is also available on MyContiweb. This online platform is updated daily and includes a dashboard with an overview of your printing press lines and daily production times, performance data, and energy consumption, giving you full control over your equipment.

Cost-benefit analysis

To make a good assessment of the purchase of a new dryer, it is important to have a clear understanding of all costs and benefits. Compared to the purchase price of a new dryer, enormous cost savings can be made in terms of maintenance, repairs, and gas and electricity consumption. In addition, a new dryer makes a significant contribution to reducing the use of fossil fuels and the CO2 emissions of your company. Many governments encourage this development in the form of subsidies on production goods that help achieve the European goal of becoming climate neutral by 2050. The EU member states have agreed that the EU must emit at least 55% less by 2030. The need to act now is great.

An indication of the potential cost savings in your specific situation can be obtained using the Sustainable Savings Estimator on our website. We would be happy to provide you with insight into the purchase value of a new dryer so that you can make an ROI calculation. Please contact your Contiweb contact person for this or schedule a meeting directly in their agenda.