- Home |

- Web offset |

- Non stop flying pasting

-

Non-stop flying pasters for web offset

-

Seamless integration with all press systems

-

Paste rates in excess of 99.7% regularly and repeatedly

Proven reliability and performance

The right non-stop flying paster for any web offset production requirement. From extensive automation to proven reliability and performance features, Contiweb splicing and pasting technology provides real advantages in the pressroom. Those advantages impact productivity, efficiency and profitability. Specifically designed for seamless integration with all press systems. They are also proven, cost-effective solutions for press rebuild and enhancement projects.

Contiweb offers two different models of non-stop flying pasters for web offset environments.

Contiweb FB

The Contiweb FB is a budget-friendly flying paster. The system is characterized by its user-friendly, easy-to-service design. The Contiweb FB has been designed to work within the newspaper, commercial and semi-commercial market segments.

Contiweb FD

The Contiweb FD flying paster combines automation, technical innovation and user-friendly features to meet advanced productivity requirements. Features such as central user interface, touchscreen controls and local operating points result in flexibility and high performance. The Contiweb FD paster has a shaftless A.C. drive system for precise synchronization with press components. The Contiweb FD paster has the breakthrough capacity to paste reels that are 1.524 millimeters (60 inches) in diameter. The large reel diameters can increase splice intervals, reducing labor requirements and opportunities for web breaks.

Advantages

- Successful pasting rates exceeding 99.7 percent

- Low waste

- High uptime

- Easy paste preparation

Features

- Comprehensive automation

- Integrated infeeds for constant web tension

- User-friendly interface

- Automated reel handling

- Contiweb web data (optional)

- Contiweb FD with paste reels up to 1.524 mm (60'') in diameter

Flying pasting

Ultimate performance

Frequently Asked Questions

Below you find the answers to some commonly asked questions about this equipment.

The splice preparation for automatic splicing is a quick and straightforward task that only takes 2 minutes to complete. It can be easily performed while the production is ongoing. The operator's involvement is minimal and involves applying a linear adhesive tape for the straight-tape splice on the paper. The time required for splice preparation is limited to the actual preparation process itself.

If there are multiple buffer positions for paper reels available, the operator has the option to prepare and set up several paper reels for automatic changeover. This allows the operator to work on other tasks while the prepared reels are ready for seamless transitions.

Contiweb's non-stop flying pasters allow you to easily splice over to papers of varying coatings and weights. This feature is particularly beneficial for short and fast-changing printing jobs. Additionally, you can effortlessly utilize rest reels.

The Contiweb non-stop flying pasters are equipped with a standard overlap splice mechanism. In an overlap splice, the expiring roll and the new roll overlap, with the leading edge of the new roll positioned on top of the trailing edge of the expiring roll. This overlap is secured using adhesive tape. Overlap splices are known for their simplicity and reliability, allowing for seamless roll changes during the printing process. Contiweb non-stop flying pasters have a successful splicing rate of over 99.7%.

As an optional feature a tail cutter can be installed, to remove the loose end of the previous web that occurs after a paste cycle. By removing the tail, potential disturbances in the folding process are eliminated.

The Contiweb FD non-stop flying paster is equipped to handle reels with a diameter of up to 1,524 mm (60 inches) with a maximum weight of 7,500 kg, which provides a multitude of advantages and benefits for printing operations. It enables a significant increase in paper capacity, reduces the number of required pastes, lowers costs, minimizes web break risks, and provides operational flexibility for web operations, particularly those with multiple presses. This advanced capability sets a new benchmark in reel processing, revolutionizing the efficiency and performance of printing operations.

The Contiweb FB is available in two versions to cater to specific needs. A version designed for newspaper applications with a reel weight capacity of 1,000 kg and a version tailored for (semi-) commercial applications with a higher reel weight capacity of 1,600 kg. The FB can handle reels with a maximum diameter of 1,270 mm (50 inches).

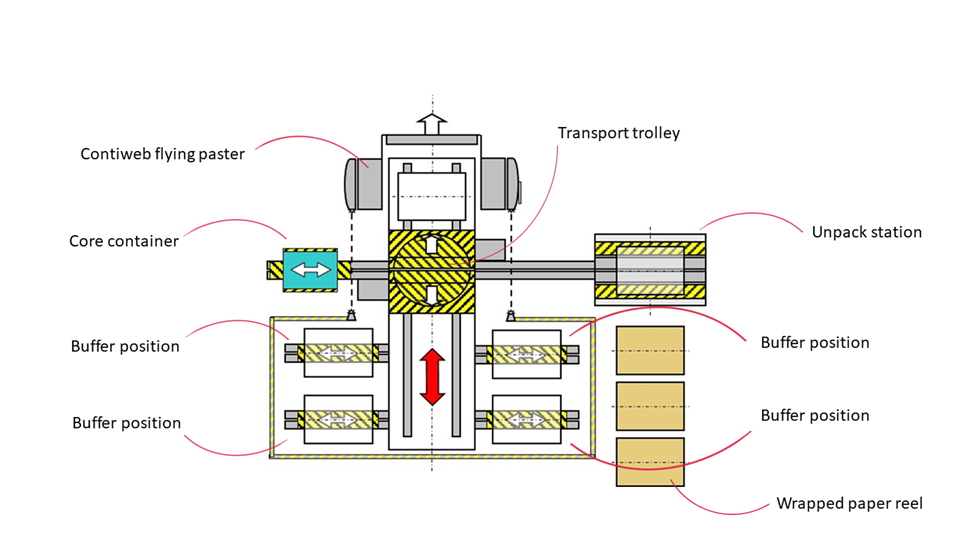

Contiweb offers comprehensive reel logistics systems that can be customized to complement its state-of-the-art non-stop flying pasters. Stand-alone storage solutions and reel buffering systems are defined by advanced capabilities and ultimate reliability. The objective is to minimize the required operator attendance whilst ensuring operational reliability, thus reducing costs. In a system with four buffer positions, up to seven reels (one at each buffer position, one in the waiting position and two in the paster) can be prepared at the same time, and no further operator involvement is required until all seven reels are being used, as the empty reels are automatically collected in the core container. You can see an example of this set up below.

Contiweb extensive experience in designing systems for commercial web applications and for newspaper applications requiring an interface with multiple pasters. The additional Contiweb advantages are full automation and complete hardware and software integration with Contiweb non-stop flying pasters and press systems. No third party involvement is required for the installation and electronic integration of the reel logistics system with the reel stands.

Contiweb offers a comprehensive range of service programs for its non-stop flying pasters to ensure optimal customer support and long-term equipment performance. When you choose Contiweb equipment, you enter into a lasting partnership built on mutual commitment, enabling continuity in the Heat Set Web Offset market. Our Service Support Agreements are designed based on these fundamental principles.

We provide four distinct packages that cater to various needs and maintenance philosophies. The key objectives of our service programs are as follows:

- Ensure top level customer service

- Increase uptime

- Safeguard low operating costs

- Ensure compliance and sustainability

- Keep maintenance costs predictable and competitive

Spare parts for Contiweb non-stop flying pasters are conveniently available in the Contiweb Parts Webshop. Sign up for an account and gain free access to Contiweb machine manuals and parts books, saving you valuable time by filtering your search for specific machine parts.

Plus, explore our Uptime Kits, specially curated with essential components to minimize downtime in the event of breakdowns, ensuring you have the necessary parts readily available in your own facility. Streamline your maintenance and keep your operations running smoothly with Contiweb.

In today's uncertain economic climate, investing in new capital equipment can pose challenges for many companies. Considering used machines can be an intriguing alternative.

Contiweb recognizes this need and maintains a dynamic inventory of used non-stop flying pasters. These machines undergo meticulous inspection, repairs, and, if desired, upgrades to ensure their quality and reliability. When a used piece of equipment leaves Contiweb's facilities, it is designated as Certified Pre-Owned, providing customers with added confidence. Furthermore, Contiweb offers a 6-month warranty with each Certified Pre-Owned machine.

Would you like to know more?

If you are interested in our flying pasting solutions for web offset production lines, then please don't hesitate to contact us!

Sales contact

Rob Bosman

Sales Director

+31 485 597 111

sales@contiweb.com