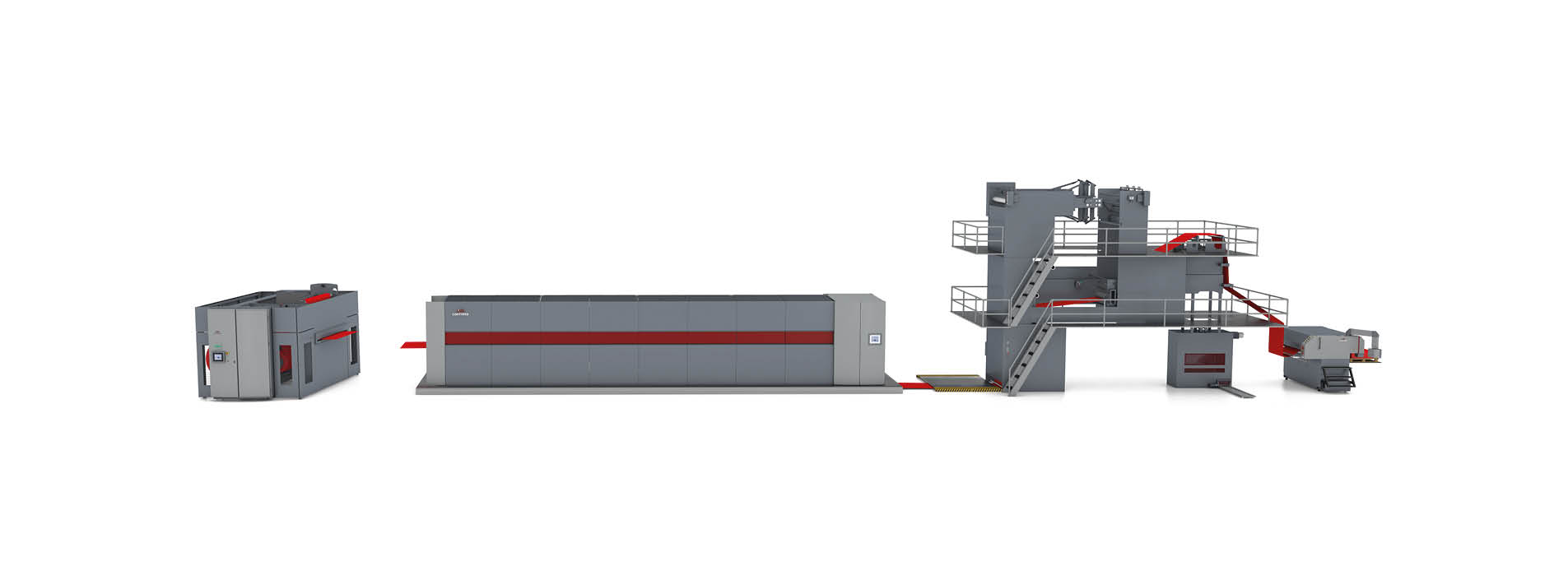

Auxilary equipment from the market leader

Contiweb has developed innovative auxiliary equipment for web offset presses and continues to set the industry standard for quality, efficiency and reliability through its innovative systems. Compatible with increasing web widths and high speed processes, these products are designed to improve up time and allow short run applications.