Use your web inkjet press to the max

Digital printing has entered the maturity phase, which means that printing companies will need to continuously upgrade the performance of their presses to meet the evolving expectations of the commercial printing industry. And to do that, they will be looking for robust, technically-advanced auxiliary equipment, backed by expert service and support. Contiweb will be there to provide it.

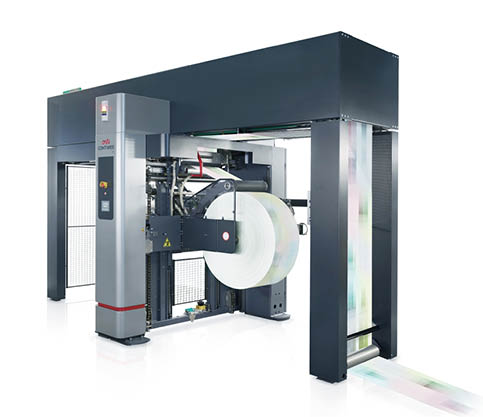

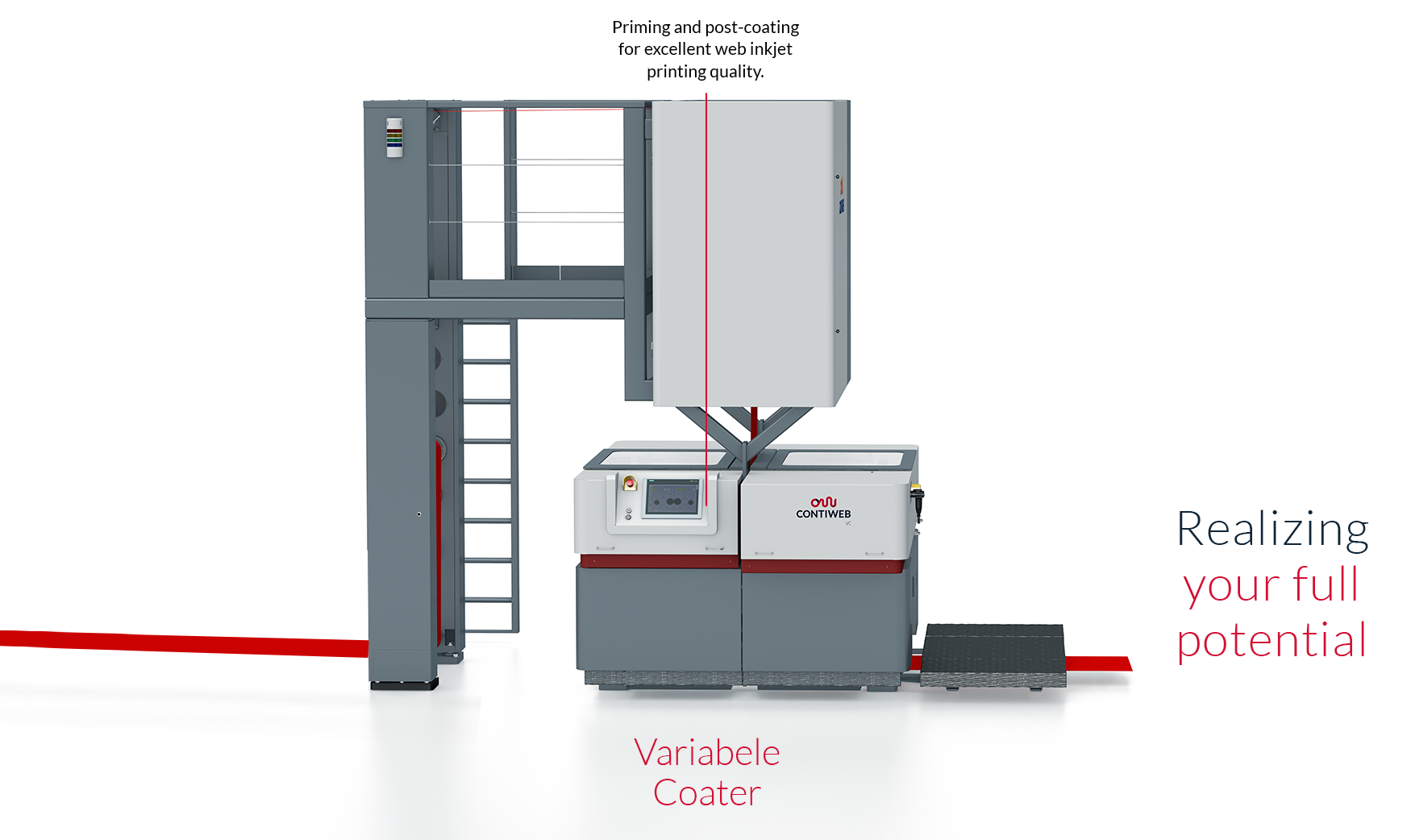

Post-coating

The Contiweb Variable Coater (VC) is a high-end system that can post-coat paper after printing it. The VC uses the patented automated metering technology to very precisely apply the coating layer on the web, causing no standstill during a web width change or when changing the coating layer thickness.